What is Rogers 4350B PCB?

Rogers 4350B PCB provider. RO4350B laminates provide tight control on dielectric constant (Dk) and maintain low loss while utilizing the same processing method as standard epoxy/glass. Available at a fraction of the cost of conventional microwave laminates, RO4350B laminates do not require the special through-hole treatments or handling procedures as PTFE based materials. These materials are UL 94 V-0 rated for active devices and high power RF designs.

Features

- Dk of 3.48 +/- 0.05

- Dissipation factor of 0.0037 at 10 GHz

- Low Z-axis coefficient of thermal expansion at 32 ppm/°C

Benefits

- Processes like FR-4 at lower fabrication cost

- Competitively priced

- Excellent dimensional stability

Rogers 4350B PCB material stands out as a high-frequency laminate crucial for crafting printed circuit boards (PCBs). Crafted by Rogers Corporation, renowned for its cutting-edge materials across various applications, this laminate finds its niche in the realm of electronics.

Tailored for high-frequency and high-performance scenarios, Rogers 4350B boasts low dielectric constant and minimal signal loss features. Its application prowess extends to RF (radio frequency) and microwave circuits, making it an ideal choice for critical areas like communication systems, radar systems, and high-frequency electronic devices.

The distinctive attributes of Rogers 4350B, encompassing dielectric constant, thermal stability, and mechanical properties, position it favorably for circuit designers working in the realm of high frequencies. Opting for specialized materials such as Rogers 4350B becomes instrumental in upholding the reliability and efficacy of electronic devices operating in demanding environments.

What is the Functionality of Rogers 4350B?

Rogers 4350B emerges as a linchpin in the electronics landscape, functioning as a high-frequency laminate tailored for the intricate world of printed circuit boards (PCBs). Unraveling its functional intricacies reveals a tapestry of attributes:

Precision in High-Frequency Realms: Precision takes center stage as Rogers 4350B steps into the limelight, catering to applications where high-frequency performance is non-negotiable. It’s a virtuoso in the realms of RF (radio frequency) and microwave circuits.

Signal Integrity Champion with a Low Dielectric Constant: A guardian of signal integrity, this material wields a low dielectric constant as its secret weapon. This characteristic becomes a silent maestro in scenarios where preserving signal quality is an absolute imperative.

Whispering Minimal Signal Loss: Whispers of minimal signal loss echo through circuits adorned with Rogers 4350B. Its low loss characteristics play a pivotal role, orchestrating a symphony of efficiency in high-frequency realms like communication systems and radar technology.

Thermal Resilience: Against the backdrop of temperature variations, Rogers 4350B stands resilient. Its thermal stability becomes a shield, safeguarding electronic devices against the unpredictable nuances of operating conditions.

Mechanical Fortitude: Beyond the dance of electrons, this material flexes its mechanical muscles. Robust mechanical properties make it a stalwart choice, adding an extra layer of reliability to a diverse array of electronic devices.

In essence, Rogers 4350B’s functionality unfolds as a tale of precision, signal integrity mastery, and resilience, making it a sought-after protagonist in the intricate narrative of high-frequency electronic applications.

What Types of Rogers 4350B PCB Are There?

Rogers 4350B PCBs exhibit versatility through a spectrum of types, each tailored to meet distinct application needs. The variations encompass differences in thickness, copper cladding, and specialized properties. Here’s a glimpse into some notable types:

Rogers 4350B Standard: The foundational variant, offering a well-rounded set of properties suitable for a broad range of high-frequency applications.

Rogers 4350B LoPro (Low Profile): Engineered with a reduced-profile copper foil, this type minimizes conductor loss, enhancing insertion loss performance. It’s a preferred choice when mitigating signal loss is a top priority.

Rogers 4350B Enhanced Thermal Management: Some variants prioritize enhanced thermal management, making them apt for applications where efficient heat dissipation is a key consideration.

Rogers 4350B High-Dk: Tailored for applications requiring a higher dielectric constant (Dk), this variant is deployed in designs where achieving specific impedance levels is paramount.

Rogers 4350B Mixed Dielectric Stackups: PCBs can be configured with mixed dielectric stackups, combining Rogers 4350B with other materials to achieve bespoke electrical or mechanical characteristics suited to the application.

Navigating the array of Rogers 4350B PCB types involves consulting manufacturer specifications and guidelines. Factors such as electrical performance, thermal dynamics, and the unique requirements of the electronic system under development guide the selection process.

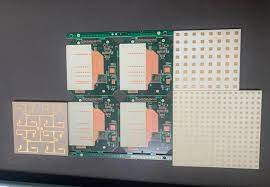

How is Rogers 4350B PCB Related to IC Packaging?

The collaboration between Rogers 4350B PCB and IC packaging is akin to a carefully choreographed dance, where each partner contributes to the seamless performance of high-performance electronic circuits. Let’s explore this partnership through a different lens:

Foundation of Integration: Rogers 4350B PCB takes center stage as the reliable foundation for IC packaging. It provides the necessary groundwork upon which integrated circuits find their place, creating a sturdy stage for their intricate performances.

Synchronized Frequencies: The unique attributes of Rogers 4350B, characterized by a low dielectric constant and minimal loss, synchronize effortlessly with the demands of high-frequency applications. This synchronization becomes particularly crucial for integrated circuits operating at frequencies where signal fidelity is non-negotiable.

Sentinel of Signal Purity: In the nuanced realm of integrated circuits, where signals traverse intricate paths, Rogers 4350B assumes the role of a sentinel. Its low dielectric constant acts as a guardian, ensuring the purity of signals and minimizing any loss along the circuit journey.

Thermal Pas de Deux: Introducing a graceful thermal pas de deux, specific variations of Rogers 4350B excel in thermal management. The dance of efficient heat dissipation becomes an integral part of the performance, safeguarding the reliability and longevity of the encapsulated integrated circuit.

Elegance in Material Composition: The artistry unfolds in mixed dielectric stackups, where Rogers 4350B collaborates with other materials. This composition allows for an elegant customization of electrical and mechanical properties, adapting to the unique nuances of the integrated circuit’s requirements.

In essence, the synergy between Rogers 4350B PCB and IC packaging is a dance of precision and elegance, where the substrate becomes a canvas for high-frequency harmonies, signal purity, and thermal grace in the enchanting world of integrated circuits.

What are the Differences Between Rogers 4350B PCB and Conventional PCBs?

Rogers 4350B PCBs and conventional PCBs navigate distinct trajectories, each marked by unique features. Let’s embark on a comparative journey, unraveling the differences that shape their identities:

Material Symphony:

Rogers 4350B PCBs: Composed with specialized high-frequency laminates, a melodic fusion of woven glass reinforced hydrocarbon/ceramic layers. Tailored virtuosos for the RF and microwave stage.

Conventional PCBs: Echo the familiar tunes of FR-4, an epoxy-based laminate with woven glass reinforcement, orchestrating a versatile performance in the realm of general electronic applications.

Dielectric Divergence:

Rogers 4350B PCBs: Dance to the rhythm of a low dielectric constant, a choreographic masterpiece beneficial in the high-frequency ballroom, where signal loss takes center stage.

Conventional PCBs: Embrace a variable dielectric constant, with FR-4 variants potentially striking a different chord compared to the specialized harmony of Rogers 4350B.

Loss Tangent Tale:

Rogers 4350B PCBs: Weave a story of a low loss tangent, crafting a narrative of minimal signal loss especially crucial in the intricate performance of high-frequency circuits.

Conventional PCBs: Contribute to the saga with potentially higher loss tangent nuances, resulting in a distinctive flavor of signal loss.

Application Synchrony:

Rogers 4350B PCBs: Take the spotlight in high-frequency theaters, particularly in RF and microwave circuits, where signal integrity commands an unwavering presence.

Conventional PCBs: Embrace a versatile role, cost-effectively gracing the stages of a diverse array of electronic applications.

Thermal Ballet:

Rogers 4350B PCBs: Perform an elegant thermal ballet, exhibiting enhanced stability to temperature variations, ensuring a seamless performance under changing conditions.

Conventional PCBs: Contribute to the thermal ensemble, with properties varying based on the specific material’s solo, potentially lacking the finesse of specialty counterparts.

Cost Overture:

Rogers 4350B PCBs: Enter the stage with a grandiose cost, a reflection of the specialized nature and advanced properties that define their performance.

Conventional PCBs: Take on the pragmatic role of a cost-effective ensemble, catering to a broad spectrum of applications with economic resonance.

In conclusion, the selection between Rogers 4350B PCBs and conventional PCBs emerges as a nuanced decision, with each finding its place in the symphony of electronic design based on the specific needs of the performance.

What is the Structure and Production Technology of Rogers 4350B PCB?

The creation of Rogers 4350B PCBs involves a meticulous blend of specialized materials and advanced production techniques designed for high-frequency performance. Here’s a breakdown of the structure and production technology:

Structure:

Foundation Material: The heart of Rogers 4350B PCBs lies in the Rogers 4350B laminate, a composite material incorporating hydrocarbon/ceramic elements reinforced with woven glass.

Conductive Layer: Copper takes the stage as the primary conductive layer, bonded to the surface of the Rogers 4350B laminate. This layer forms the intricate pathways for electronic signals.

Layer Configuration: The flexibility of Rogers 4350B PCBs allows for multi-layer configurations, accommodating complex circuitry. Each layer may house its unique copper traces, contributing to the overall functionality.

Dielectric Harmony: Acting as the dielectric material between conductive layers, the Rogers 4350B laminate brings harmony with its low dielectric constant—a pivotal attribute for achieving high-frequency prowess.

Production Technology:

Material Alchemy: The production journey commences with the careful selection of Rogers 4350B laminate. This choice sets the stage for the exceptional electrical properties required.

Panel Artistry: The laminate undergoes preparation in panel form, where the dimensions are tailored according to the envisioned specifications of the final PCBs.

Copper Unveiling: Copper foil makes its entrance, becoming an integral part of the laminate through lamination. The thickness of this copper foil is finessed to meet the electrical and thermal demands of the PCB.

Circuit Choreography: The intricate dance of circuit patterns takes shape through processes like photolithography. Photoresist, exposed to light through a carefully crafted mask, unveils the desired copper traces as unwanted portions are etched away.

Layer Symphony: For designs requiring multiple layers, the layers of copper-clad laminate come together in a harmonious lamination process. Heat and pressure unite them, forming a cohesive structure.

Drilling Precision: Holes are drilled strategically to accommodate component leads and vias, ensuring the necessary connectivity between different layers. These holes are then plated to establish conductive pathways.

Surface Elegance: The final act involves applying a surface finish to protect the copper traces and facilitate soldering. Choices like HASL, ENIG, or OSP provide the finishing touches, ensuring durability and solderability.

The orchestration of these steps yields Rogers 4350B PCBs, finely tuned for the demands of high-frequency applications. The production process demands precision and adherence to specific practices to unlock the full potential of these advanced circuit boards.

FAQs (Frequently Asked Questions):

How does Rogers 4350B differ from traditional PCBs?

Rogers 4350B stands apart due to its unique material composition and high-frequency performance. In contrast, traditional PCBs like FR-4 are more versatile but may not meet the precision demands of high-frequency circuits.

What’s the cost consideration for Rogers 4350B PCBs?

Rogers 4350B PCBs tend to be pricier compared to conventional counterparts. The elevated cost reflects the specialized nature of the material and its advanced characteristics.

Can Rogers 4350B PCBs accommodate multilayer designs?

Absolutely, Rogers 4350B PCBs are versatile for multilayer configurations, allowing the creation of intricate circuits with multiple layers.

Which surface finishes are compatible with Rogers 4350B PCBs?

Common surface finishes include HASL, ENIG, and OSP, providing protective layers and facilitating soldering for Rogers 4350B PCBs.

Is Rogers 4350B suitable for applications with high thermal demands?

Yes, Rogers 4350B PCBs excel in thermal stability, making them ideal for applications facing challenging temperature variations.

How should one choose between Rogers 4350B and other high-frequency materials?

The selection hinges on specific design needs. Consider factors like dielectric constant, loss tangent, thermal properties, and cost when choosing a high-frequency material.

Can Rogers 4350B PCBs be used in 5G applications?

Certainly, Rogers 4350B PCBs are well-suited for 5G applications, where high-frequency performance and low signal loss are paramount for seamless communication.

Conclusion

In conclusion, Rogers 4350B PCBs stand as specialized marvels in the realm of high-frequency electronics. With a unique composition featuring Rogers 4350B laminate, these PCBs exhibit low signal loss, superior signal integrity, and exceptional thermal stability. Commonly employed in RF and microwave circuits, they cater to applications such as communication systems and radar technology, where precision in high-frequency performance is non-negotiable.

The distinctive properties of Rogers 4350B, including a low dielectric constant and minimal loss tangent, set it apart from conventional PCBs like FR-4. While these advanced PCBs come at a higher cost, their specialized nature and elevated performance make them a preferred choice for applications demanding unparalleled precision.

Rogers 4350B PCBs offer versatility in multilayer designs, allowing the creation of complex circuits to meet diverse electronic requirements. The choice of surface finishes, including HASL, ENIG, and OSP, further enhances their durability and solderability.

In a world witnessing the advent of 5G technology, Rogers 4350B PCBs prove their mettle, aligning seamlessly with the demands of high-frequency communication. The decision between Rogers 4350B and other high-frequency materials involves a careful consideration of factors such as dielectric constant, loss tangent, thermal properties, and cost, tailored to the specific needs of the electronic design.

In essence, Rogers 4350B PCBs emerge not just as circuit boards but as instrumental components in the symphony of advanced electronics, where precision, reliability, and high-performance capabilities take center stage. Whether orchestrating the intricacies of communication systems or navigating the complexities of radar technology, Rogers 4350B PCBs leave an indelible mark in the landscape of electronic engineering.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer