What is Rogers 4360G2 PCB?

Rogers 4360G2 PCB Maker. RO4360G2 laminates are the first high dielectric constant (Dk) thermoset laminate that can be processed similar to FR-4. These materials are lead-free process capable and offer better rigidity for improved processability in multi-layer board constructions, while reducing material and fabrication costs. RO4360G2 laminates can be paired with RO4400™ series prepreg and lower-Dk RO4000® laminate in multi-layer designs.

Features

- Dk of 6.15 +/- 0.15

- Low dissipation factor of 0.0038 at 10 GHz

- High thermal conductivity of 0.75 W/(m-K)

- Low Z-axis coefficient of thermal expansion at 28 ppm/°C

- High Tg greater than 280 °C TMA

Benefits

- Automated assembly compatible

- Plated through-hole reliability

- Environmentally friendly – lead free process compatible

- Efficient supply chain and short lead times makes for cost effective material option

When talking about “Rogers 4360G2 PCB,” you’re essentially delving into a type of printed circuit board (PCB) crafted by Rogers Corporation. Rogers Corporation has gained recognition for churning out high-performance materials utilized in diverse electronic applications, and PCBs fall under this purview.

Rogers 4360G2 stands out as a particular material grade devised by Rogers expressly for PCB fabrication. PCBs serve as pivotal components in electronic gadgets, furnishing a stage for the interconnection and support of electronic elements. The distinct feature of Rogers 4360G2 lies in its prowess at high frequencies, making it a preferred choice for applications where minimal loss and heightened reliability are paramount—think radio frequency (RF) and microwave circuits.

The performance metrics of Rogers 4360G2, encompassing its dielectric constant, loss tangent, and thermal stability, render it apt for exacting electronic applications, particularly those in the high-frequency spectrum. Engineers and designers routinely opt for specific PCB materials based on their electrical and mechanical attributes, tailoring them to meet the prerequisites of the intended electronic device.

What are the Functions of Rogers 4360G2 PCB?

Within the realm of electronic applications, the Rogers 4360G2 PCB assumes a multifaceted role, orchestrating functions that cater to the imperatives of high-frequency precision, minimal signal dissipation, and unwavering reliability. Let’s unravel the distinct roles it plays:

Elevated Frequency Proficiency: Tailored for environments pulsating with high frequencies, such as RF and microwave circuits, the Rogers 4360G2 PCB stands out as a maestro in handling signals at the upper echelons of the frequency spectrum.

Guardian of Signal Integrity: At its core, this PCB strives to be a custodian of signal integrity, strategically minimizing the loss of signals, especially crucial in the intricate dance of high-frequency circuits. The Rogers 4360G2 is architected to conduct signals with finesse, preserving their essence.

Reliability Sentinel: Stepping into the role of a reliability sentinel, the Rogers 4360G2 PCB becomes the chosen guardian for applications where unwavering dependability is not negotiable. Its presence is an assurance of stability and performance.

Dielectric Virtuosity: The ballet of signals relies on the dielectric prowess of the PCB. The constant and tangent of loss properties of the Rogers 4360G2 play a key role, orchestrating the speed and efficiency of signal propagation with finesse.

Temperature-Resilient Virtuoso: In the face of varying temperatures, the Rogers 4360G2 PCB maintains its composure, bringing to the stage a temperature-resilient performance that ensures the show goes on, unfazed by thermal fluctuations.

Architect of Support Structures: Beyond its electronic symphony, this PCB serves as an architect, providing a meticulously structured platform for the harmonious interconnection and support of electronic components, orchestrating their collaboration.

In essence, the Rogers 4360G2 PCB dons the mantle of a virtuoso, conducting a symphony of high frequencies, signal fidelity, reliability, and structural support in the intricate ballet of electronic applications.

What are the Types of Rogers 4360G2 PCB?

In the realm of electronics, the term “Rogers 4360G2 PCB” is a nod to a particular breed of printed circuit board (PCB) meticulously fashioned using Rogers 4360G2 material. While the fundamental material remains constant, the nuances in types and configurations of these PCBs can vary based on design intricacies and application specifics. Here’s a glimpse into the potential variations:

Single-Sided Serenity: Rogers 4360G2 lends its essence as the substrate for single-sided PCBs, where copper traces gracefully adorn one side.

Double-Sided Harmony: Embracing a dual existence, these PCBs feature copper traces on both sides, with Rogers 4360G2 serving as the harmonious insulating layer nestled between.

Multilayer Symphony: Stepping into the complexity of intricate circuits, multilayer PCBs weave a symphony by stacking multiple layers of Rogers 4360G2 with copper traces, allowing for a crescendo in circuit density.

RF and Microwave Crescendo: Crafted for the grand stage of radio frequency (RF) and microwave applications, Rogers 4360G2 takes center stage with its high-frequency prowess and low loss, orchestrating a crescendo of performance.

High-Frequency Elegance: Adaptable to scenarios resonating with high-frequency signals, these PCBs choreograph an elegant dance using Rogers 4360G2, ensuring a seamless transmission ballet with minimal signal loss.

Antenna Overture: Tailored for antennas seeking the pinnacle of performance, Rogers 4360G2 PCBs compose an overture, contributing to the optimal reception and transmission of signals.

It’s paramount to grasp that the specific rendition of a Rogers 4360G2 PCB unfolds based on factors such as layer intricacy, circuit choreography, and the distinctive demands of the electronic opus at hand. Designers and engineers, akin to maestros, carefully select the composition based on the desired electrical harmonies and the bespoke requirements of the application du jour.

How does Rogers 4360G2 PCB relate to IC Package?

The synergy between Rogers 4360G2 PCB and IC packages unfolds in the realm of high-frequency applications, where their unique attributes harmonize to ensure optimal performance:

Integral Substrate for IC Packages: Rogers 4360G2 takes center stage as a preferred substrate material within IC packages. These packages encapsulate integrated circuits, and the choice of substrate becomes pivotal, especially in high-frequency environments where signal integrity is paramount.

Navigating High Frequencies: In the intricate dance of high frequencies, Rogers 4360G2 PCBs extend their influence beyond general circuitry, finding a place within the substrate of IC packages. This ensures that the substrate aligns seamlessly with the high-frequency requirements of the integrated circuits nestled within.

Efficient Signal Transmission: Rogers 4360G2’s stellar dielectric properties make it an ideal conductor for efficient signal transmission. Within IC packages, where signal paths are confined and operate at elevated frequencies, the substrate’s choice becomes a linchpin in preserving signal integrity.

Thermal Harmony: Both Rogers 4360G2 PCBs and IC packages share the stage in managing thermal considerations. The thermal stability of Rogers 4360G2 proves advantageous in applications where temperature fluctuations are a norm. In IC packages, effective thermal management is vital for the sustained reliability and performance of encapsulated integrated circuits.

RF and Microwave Maestros: The affinity of Rogers 4360G2 for RF and microwave applications finds resonance in ICs tailored for high-performance RF scenarios. The shared characteristics contribute to an orchestrated performance in applications demanding top-tier high-frequency capabilities.

In essence, the collaboration between Rogers 4360G2 PCBs and IC packages is a symphony of high-frequency precision, signal integrity, and thermal resilience, ensuring a seamless performance in the intricate ballet of electronic applications.

What are the Differences between Rogers 4360G2 PCB and Traditional PCBs?

Distinguishing between Rogers 4360G2 PCBs and traditional PCBs unveils disparities rooted in material composition and specialized characteristics:

Material Essence:

Rogers 4360G2 PCBs: Crafted with Rogers 4360G2 material as the substrate, these PCBs embody high-performance attributes tailored for high-frequency scenarios. Rogers 4360G2 boasts low loss tangent and superior dielectric properties.

Traditional PCBs: In contrast, traditional PCBs leverage materials like FR-4, a versatile substrate suitable for general electronic applications but lacking the specialized features of Rogers 4360G2.

High-Frequency Symphony:

Rogers 4360G2 PCBs: Designed for high-frequency prowess, these PCBs shine in applications demanding efficient signal transmission and minimal loss, particularly in RF and microwave circuits.

Traditional PCBs: Positioned in standard electronic applications, traditional PCBs might not exhibit the same finesse in high-frequency performance as their Rogers 4360G2 counterparts.

Loss Tangent Dynamics:

Rogers 4360G2 PCBs: Notable for a low loss tangent, Rogers 4360G2 mitigates signal loss, making it a stalwart choice for scenarios prioritizing high signal integrity.

Traditional PCBs: The loss tangent in traditional PCB materials can be higher, potentially impacting signal transmission efficiency, especially at elevated frequencies.

Dielectric Constants:

Rogers 4360G2 PCBs: Characterized by a stable and low dielectric constant, Rogers 4360G2 ensures consistent electrical characteristics, a boon in high-frequency circuits.

Traditional PCBs: Dielectric constants in traditional PCB materials may exhibit variability, lacking the same level of stability in high-frequency realms.

Application Context:

Rogers 4360G2 PCBs: Thrive in high-frequency environments, particularly in RF and microwave circuits, where low loss and high signal integrity are paramount.

Traditional PCBs: Flourish in standard electronic applications where the demand for high-frequency performance takes a back seat to broader electronic considerations.

In essence, the divergence lies in the material essence and the specialized characteristics tailored for the intricate demands of high-frequency applications in Rogers 4360G2 PCBs, while traditional PCBs find their forte in standard electronic landscapes.

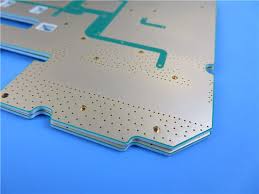

What is the Main Structure and Production Technologies of Rogers 4360G2 PCB?

The construction and fabrication of a Rogers 4360G2 PCB entail a meticulous blend of materials and production techniques, culminating in a high-performance printed circuit board. Let’s delve into the main structural components and the intricate dance of production technologies:

Foundation Material:

Rogers 4360G2 Laminate: At the heart of the PCB lies the Rogers 4360G2 laminate, chosen for its exceptional attributes like a low loss tangent, stable dielectric constant, and reliable thermal stability. This material forms the foundational substrate for the entire structure.

Conductive Pathways:

Copper Foil Layers: Conduction takes shape through copper foil layers. These layers, etched into traces and pads, enable the flow of electrical signals across the PCB surface.

Insulating Layers:

Prepreg Layers: Interspersed between copper layers, prepreg layers, also derived from Rogers 4360G2 material, act as dielectric layers. They provide insulation, maintaining separation between conductive traces.

Layer Harmony:

Multilayer Configuration: The PCB may adopt a multilayer structure, depending on the complexity of the circuit. Copper and prepreg layers harmoniously stack together, following a design that suits the intricacies of the electronic assembly.

Precision Fusion:

Alignment and Lamination: Before lamination, layers undergo precise alignment, a crucial step for maintaining circuit accuracy. Lamination, conducted under elevated temperature and pressure, fuses the layers into a cohesive unit.

Conduit Creation:

Drilling: Precision drilling carves out holes for vias and component mounts. The accuracy of these holes is paramount for the integrity of the circuit.

Interconnect Enhancement:

Copper Plating: Through-hole plating enriches the drilled holes with copper, facilitating electrical continuity across different layers and components.

Surface Shielding:

Surface Finish Application: To shield exposed copper surfaces from oxidation and ensure solderability, a surface finish is applied. Common methods include HASL, ENIG, or OSP.

Aesthetic Markings:

Silkscreen and Legend Printing: Silkscreen and legend printing add an aesthetic touch, incorporating component markings, reference designators, and logos onto the PCB surface, aiding in the assembly process.

Quality Serenade:

Inspection and Testing: The final act involves rigorous inspection and testing to validate adherence to design specifications and quality benchmarks. Checks encompass dimensional accuracy, electrical continuity, and impedance control.

In essence, the production journey of a Rogers 4360G2 PCB is a symphony of material precision, layer fusion, and meticulous quality checks, resulting in a high-performance circuit board tailored for the demands of high-frequency applications.

FAQs about Rogers 4360G2 PCB

Advantages of Rogers 4360G2 PCBs?

Advantages encompass high-frequency precision, minimal signal loss, superior signal integrity, and suitability for RF and microwave applications, ensuring reliability in critical electronic systems.

Common Applications of Rogers 4360G2 PCBs?

Widely used in communication systems, aerospace, medical devices, and other electronic systems where high-frequency precision is paramount.

How does it Differ from Traditional PCB Materials?

Differs from traditional materials like FR-4 due to specialized characteristics designed for high-frequency applications, offering lower loss tangent and enhanced dielectric properties.

Suitability for Multilayer Configurations?

Yes, Rogers 4360G2 PCBs can be configured in multilayer structures, catering to the demands of complex circuits while maintaining high-frequency performance.

Compatible Surface Finishes?

Common finishes include HASL, ENIG, and OSP, selected based on specific application requirements.

Quality Assurance During Production?

Quality is ensured through stringent inspection and testing, covering dimensional accuracy, electrical continuity, and impedance control.

Thermal Stability of Rogers 4360G2 PCBs?

Exhibits excellent thermal stability, enabling PCBs to withstand varying temperatures without compromising performance.

Considerations in Designing with Rogers 4360G2 PCBs?

Design considerations include understanding the material’s electrical properties, selecting appropriate stackup configurations, and ensuring precise impedance control for high-frequency applications.

Conclusion

In conclusion, Rogers 4360G2 PCBs represent a pinnacle in high-frequency electronic design, with their specialized material offering unique advantages. The low loss tangent, stable dielectric constant, and excellent thermal stability make them integral components in applications demanding precision and reliability, especially in RF and microwave circuits.

The construction of Rogers 4360G2 PCBs involves a carefully orchestrated production process, encompassing the selection of Rogers 4360G2 laminate, copper foil layers, prepreg layers, and meticulous layer stacking. The multilayer configurations, precise alignment, drilling, copper plating, and application of surface finishes contribute to the creation of a high-performance circuit board.

As seen in the FAQs, Rogers 4360G2 PCBs find applications across diverse industries, including communication systems, aerospace, and medical devices. The material’s ability to withstand varying temperatures and maintain signal integrity positions it as a cornerstone in electronic systems where performance is paramount.

In the ever-evolving landscape of electronic design, Rogers 4360G2 PCBs stand as exemplars of material innovation, enabling engineers to meet the demands of high-frequency environments. The continuous pursuit of excellence in design and production ensures that these PCBs will remain vital components in advancing technology and achieving unparalleled performance in critical electronic systems.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer