What is Rogers RT/duroid 5880 PCB?

Rogers RT/duroid 5880 PCB manufacturing. RT/duroid 5880 laminates has a low dielectric constant (Dk) and low dielectric loss, making them well suited for high frequency/broadband applications. Helping to maintain the Dk uniformity are the randomly oriented microfibers reinforcing the PTFE composites.

Features

- Dk or 2.20 +/- .02

- Dissipation factor of .0009 at 10GHz

- Low moisture absorption

- Isotropic

Benefits

- Uniform electrical properties over wide frequency range

- Easily cut, shared and machined to shape

- Resistant to solvents and reagents used in etching or plating edges and holes

- Ideal for high moisture environments

- Well-established material

- Lowest electrical loss for reinforced PTFE material

Rogers RT/duroid 5880 represents a printed circuit board (PCB) material meticulously crafted by Rogers Corporation. PCBs, the unsung heroes of electronic devices, seamlessly provide both structural support and electrical interconnections among diverse components. Renowned for its prowess in high-frequency domains, RT/duroid 5880 takes center stage in applications spanning the realms of RF (radio frequency) and microwave frequencies.

This particular PCB variant boasts distinctive traits, including a diminished dielectric constant and an inconspicuous loss tangent. These characteristics are pivotal in safeguarding signal integrity, especially in the realm of heightened frequencies. Furthermore, its design exhibits a commendable thermal stability, catering to scenarios where fluctuations in temperature pose a formidable challenge.

Designers are often drawn to the allure of RT/duroid 5880 for niche applications such as high-frequency communication systems, radar setups, and other RF/microwave circuits where surgical precision in electrical performance is paramount. The material’s intrinsic properties play a pivotal role in assuaging signal distortion concerns, ensuring unwavering performance in environments characterized by the demanding nature of high-frequency operations.

What are the Key Functions of 5880 PCB?

In the intricate dance of electronic components, the Rogers RT/duroid 5880 PCB material takes on a dynamic role, executing a symphony of functions:

Navigating High-Frequency Realms: With a tailored finesse, the RT/duroid 5880 material steps into the limelight, showcasing its prowess in the realms of high-frequency intricacies, particularly in RF and microwave circuits.

Sentinel of Signal Purity: Armed with a low dielectric constant and an inconspicuous loss tangent, the material becomes a vigilant guardian, warding off the specter of signal distortion. This becomes a linchpin in scenarios where the sanctity of signal integrity is non-negotiable, notably in the intricate landscapes of communication and radar systems.

Resilient in the Face of Temperature Flux: Unperturbed by the whims of temperature, the PCB material stands resilient, boasting commendable thermal stability. This resilience becomes a cornerstone in environments where temperature fluctuations play the role of a perennial adversary.

Unwavering Performance in High-Frequency Arenas: Crafted with meticulous consideration, the design and material properties of RT/duroid 5880 harmonize to deliver a cadence of unwavering and consistent performance in the challenging terrain of high-frequency applications. This makes it the material of choice for circuits demanding surgical precision and unwavering stability, notably in the realms of aerospace and defense.

Versatility Unleashed: Far from being confined to a singular role, RT/duroid 5880 unfurls its wings in the vast expanse of versatility. Its applications span a kaleidoscope of high-frequency circuits, seamlessly adapting to the dynamic demands of communication systems, radar orchestrations, and satellite communications.

Mitigating the Ebb of Energy Losses: With a low loss tangent, RT/duroid 5880 takes an active stance in curbing the ebb of energy losses within the circuit, elevating the efficiency of high-frequency applications.

Reliable Stage for Wireless Components: Beyond its ostensible functions, the material steps onto the stage as a reliable substrate, providing a robust foundation for antennas and transceivers in the intricate ballet of wireless communication systems.

In essence, the RT/duroid 5880 PCB material emerges not just as a participant but as a maestro in the symphony of high-frequency precision, signal fidelity, thermal resilience, and adaptability across the diverse spectrum of electronic landscapes.

What are the Different Types of Rogers RT/duroid 5880 PCB?

The Rogers RT/duroid 5880 PCB material family unfolds a tapestry of variations, each tailored to meet specific demands across diverse applications. These nuanced variants, each with its distinct characteristics, bring forth targeted enhancements. Here’s a glimpse into this dynamic spectrum:

RT/duroid 5880: The foundational variant, celebrated for its excellence in navigating high-frequency landscapes. Marked by a low dielectric constant and loss tangent, it seamlessly integrates into a myriad of RF and microwave applications.

RT/duroid 5880LZ: This variant takes center stage with a focus on refining low loss characteristics. It emerges as the preferred choice in scenarios where the imperative is to minimize signal loss, often finding its purpose in high-frequency communication systems and radar configurations.

RT/duroid 5880N: Variants bearing the “N” insignia signify tailored modifications or enhancements to the core material. These may include advancements in thermal stability or other pivotal attributes.

RT/duroid 5880N/LTCC: An innovative amalgamation with Low-Temperature Co-fired Ceramic (LTCC) technology, this variant seamlessly marries the strengths of RT/duroid 5880 with ceramic-like properties. It becomes the go-to solution for applications seeking a harmonious blend of high-frequency performance and ceramic characteristics.

RT/duroid 5880N/TL: The “TL” moniker hints at a Thin Layer variant, presenting a leaner profile of the RT/duroid 5880 material. This proves to be a strategic choice in applications constrained by spatial limitations.

As the technological landscape evolves, so too do the contours of product lines and variants. Engineers, in their pursuit of optimal solutions, make judicious selections, factoring in the distinctive requirements of their applications. Considerations such as frequency, signal fidelity, thermal resilience, and spatial constraints play a pivotal role in this dynamic decision-making process. For the latest insights, engaging with Rogers Corporation or authorized distributors stands as the recommended avenue.

How Does 5880 PCB Interact with IC Packaging?

The intricate dance between a 5880 PCB (Printed Circuit Board) and IC (Integrated Circuit) packaging unfolds across a spectrum of considerations, weaving a tapestry that defines the performance and reliability of electronic devices. Here’s an exploration of the nuanced interaction between these components:

Harmonizing High-Frequency Signals: Tailored for high-frequency prowess, the RT/duroid 5880 PCB material takes center stage, orchestrating the seamless flow of high-frequency signals between ICs and other circuit elements. Its design intricately aligns with the demands of RF (Radio Frequency) and microwave circuits.

Quest for Impedance Synchrony: The pursuit of optimal signal integrity is an art of achieving impedance synchrony. The characteristics of the 5880 PCB material, including a low dielectric constant and low loss tangent, become instrumental in attaining the delicate balance needed for reliable communication between ICs.

Navigating the Thermal Landscape: As ICs emit heat during operation, effective thermal dissipation emerges as a critical consideration. The inherent thermal stability of the RT/duroid 5880 material plays a crucial role in managing the thermal landscape on the PCB, thus influencing the overall thermal performance of the integrated circuits.

Strategic Package Dimensions and Mounting: The physical dimensions and mounting strategies of IC packages on the PCB become a canvas where engineers paint the picture of optimized signal paths and performance. Considerations around the intricacies of IC package dimensions, pin configurations, and PCB layout become pivotal in sculpting an environment conducive to optimal signal paths and minimized parasitic effects.

Aligning Material Harmonies: The symphony of material properties between the PCB and IC packaging materials is a key note in this interaction. A harmonious alignment prevents challenges such as differential thermal expansion, mitigating the risk of mechanical stresses that could compromise solder joints and overall reliability.

Mastering RF Grounding and Isolation: The art of effective grounding and isolation in high-frequency circuits is a strategic play. The RT/duroid 5880 material, coupled with sound layout practices, becomes a conductor orchestrating robust RF grounding and isolation between different ICs.

Connector Choreography: When connectors enter the stage for interfacing with external devices or other boards, the design choreography must consider the impedance characteristics of these connectors. This ensures a seamless performance, free from impedance mismatches.

In essence, the dynamic interplay between a 5880 PCB and IC packaging ventures into realms of high-frequency signal ballet, impedance poetry, thermal equilibrium, meticulous physical layout, material symphony, and strategic grounding choreography. Engineers, as virtuoso performers, navigate these considerations with precision to compose a masterpiece ensuring the reliability and efficiency of electronic devices in the intricate symphony of high-frequency applications.

What Sets 5880 PCB Apart from Conventional PCBs?

The RT/duroid 5880 PCB sets itself apart from conventional counterparts by virtue of its distinctive material composition and specialized design, honed to meet the exacting standards of high-frequency applications. Here are notable features that distinguish the 5880 PCB:

Elevated High-Frequency Performance: Engineered with a specific focus on high-frequency scenarios, the RT/duroid 5880 material excels in RF and microwave circuits. Its low dielectric constant and minimal loss tangent position it as a standout performer where maintaining signal integrity at elevated frequencies is paramount.

Exceptionally Low Loss Tangent: A defining characteristic of the RT/duroid 5880 material is its remarkably low loss tangent. This attribute translates into minimal signal losses in high-frequency circuits, contributing to heightened efficiency and superior signal quality compared to conventional PCB materials.

Robust Thermal Stability: Demonstrating commendable thermal stability, the material proves its mettle in applications characterized by fluctuating temperatures. This resilience distinguishes it from conventional PCBs that may encounter challenges in sustaining optimal performance under varying thermal conditions.

Specialized Application Focus: The RT/duroid 5880 PCB finds its niche in specialized applications, including high-frequency communication systems, radar installations, and satellite communications. Its precision in electrical performance sets it apart from conventional PCBs that may not exhibit the same level of proficiency in these specific use cases.

Material Homogeneity: Consistency in material properties is a hallmark of the RT/duroid 5880, contributing to its overall reliability. This harmonization of material characteristics between the PCB and other components, such as IC packaging, mitigates issues like differential thermal expansion, enhancing the board’s reliability.

Versatility with Precision: While tailored for high-frequency applications, the RT/duroid 5880 PCB demonstrates a versatile nature, accommodating various circuit configurations. This adaptability distinguishes it from conventional PCBs that might lack optimization for the unique demands of high-frequency environments.

Signal Fidelity Mastery: The combination of a low dielectric constant and low loss tangent plays a pivotal role in minimizing signal distortion. This meticulous attention to signal fidelity ensures that the RT/duroid 5880 PCB maintains the precision of high-frequency signals, a level of performance that conventional PCBs may not consistently achieve.

In summary, the RT/duroid 5880 PCB stands out in the electronic landscape, forging its identity through specialized material properties, exceptional high-frequency performance, low loss tangent, thermal resilience, and suitability for applications requiring precision in RF and microwave circuits. Engineers gravitate towards the RT/duroid 5880 when optimal performance in the realm of high frequencies is a non-negotiable requirement.

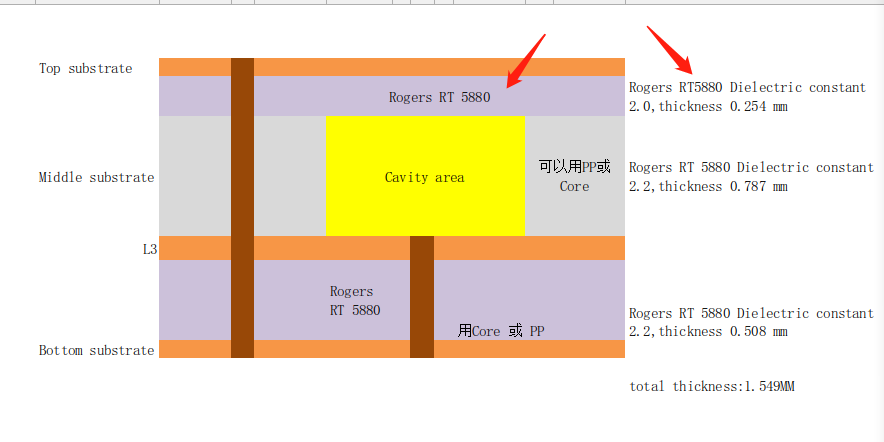

What is the Main Structure and Production Technology of 5880 PCB?

The RT/duroid 5880 PCB invites us into a world of precision and artistry, where its structured composition and production technology unfold a narrative of high-frequency excellence. Let’s embark on a journey to explore the unique facets that define this technological masterpiece:

Main Structure:

Core Brilliance: At its core lies a substrate fashioned from ceramic-filled PTFE (Polytetrafluoroethylene). This isn’t just a substrate; it’s the epitome of engineering brilliance designed for a low dielectric constant and a low loss tangent, setting the stage for unparalleled high-frequency performance.

Conductive Tapestry: Copper foil layers intricately weave across the substrate, conducting a symphony of signals. These copper layers are not mere pathways; they are the threads of a tapestry, crafting intricate conductive traces that carry the essence of electrical connectivity.

Adhesive Symphony: The layers unite in a silent symphony of adhesives, orchestrating structural harmony. These adhesives are not just bonds; they are the unseen architects ensuring stability and coherence in the intricate design.

Soldermask Guardian: A protective soldermask delicately enfolds the copper traces, standing as a guardian against solder challenges and oxidation. Beyond its protective role, it acts as an insulator, preserving the sanctity of the PCB.

Surface Finish Elegance: The final stroke of elegance comes with surface finishes like the regal ENIG (Electroless Nickel Immersion Gold) or the subtle sophistication of immersion silver. This isn’t just a finish; it’s an embodiment of elegance enhancing both aesthetics and durability.

Final Flourish: The concluding act involves a final finish and additional coatings, adding a touch of flourish to the PCB’s presentation. It’s not just an ending; it’s a celebration of the board’s functional sophistication.

Production Technology:

Material Sonata: The journey unfolds with a sonata of material selection – a carefully composed ensemble of PTFE, copper, adhesives, and protective finishes. Each material plays a unique role, contributing to the harmonic excellence of the PCB.

Lamination Ballet: The substrate and copper layers engage in a ballet of lamination, where heat and pressure dance to create a resilient bond. This isn’t just a lamination process; it’s a ballet where layers seamlessly meld into a cohesive masterpiece.

Copper Etching Choreography: The copper layers engage in a choreography of etching, sculpting circuit patterns with artistic precision. This isn’t just etching; it’s a dance that shapes both the visual and functional identity of the PCB.

Drilling Precision Sonata: Precision takes center stage in the sonata of drilling, where drill bits perform with the finesse of maestros. These drilled holes are not mere openings; they are gateways that facilitate connections and vias with a touch of artistic precision.

Soldermask Opera: The application of soldermask unfolds as an opera, a performance of coverage and exposure. It’s a protective layer that adds both functionality and visual drama to the PCB.

Surface Finish Finale: The chosen surface finish is applied as a grand finale, elevating the PCB to both functional excellence and aesthetic refinement. This isn’t just a finish; it’s the concluding note of a well-orchestrated performance.

Quality Crescendo: The grand crescendo arrives with quality control, where rigorous testing reaches its zenith. Every aspect, from electrical checks to impedance matching, undergoes scrutiny to ensure the PCB’s performance isn’t just a note but a symphony of perfection.

In essence, the production technology of the RT/duroid 5880 PCB is a symphony of materials, precision, and quality control. Each step in the process contributes to the creation of a harmonious composition, where form and function intertwine to craft a PCB that transcends the ordinary and resonates as a technological masterpiece.

Frequently Asked Questions (FAQs)

What sets RT/duroid 5880 PCB apart from traditional circuit boards, and why is it preferred for specific uses?

RT/duroid 5880 PCB distinguishes itself with specialized material properties, excelling in high-frequency scenarios where conventional boards may fall short. Its low loss tangent and thermal stability make it ideal for demanding applications.

Can RT/duroid 5880 PCB adapt to different circuit configurations?

Absolutely, the adaptability of RT/duroid 5880 PCB extends to various circuit configurations. While optimized for high-frequency scenarios, its flexibility makes it a versatile choice for diverse circuit applications.

How is the quality of RT/duroid 5880 PCB upheld throughout its production journey?

Quality control is paramount at every stage of production, encompassing comprehensive testing for electrical continuity, impedance matching, and overall reliability. This rigorous approach ensures that RT/duroid 5880 PCBs meet the highest quality standards.

What are the key features of Rogers RT/duroid 5880 PCB?

The key features include high-frequency performance, low loss tangent, thermal stability, specialized applications in RF and microwave circuits, and a consistent material composition for reliability.

In which sectors does RT/duroid 5880 PCB find predominant use?

RT/duroid 5880 PCB is a go-to solution for industries that demand top-notch high-frequency performance. It finds applications in telecommunications, aerospace for radar systems, and defense scenarios where maintaining signal integrity is critical.

Conclusion

In conclusion, Rogers RT/duroid 5880 PCB emerges as a technological masterpiece, seamlessly blending precision engineering with versatile applications. Its low dielectric constant and low loss tangent elevate it to a league of its own in the realm of high-frequency circuitry. As we unravel its intricacies, from the structured composition featuring ceramic-filled PTFE to the meticulous production processes involving lamination, copper etching, and quality control, it becomes evident that this PCB is not just a substrate but a canvas for innovation.

The standout features of RT/duroid 5880, including exceptional high-frequency performance, thermal stability, and suitability for diverse industries such as telecommunications, aerospace, and defense, underscore its significance in the realm of advanced electronics. Its ability to interact harmoniously with IC packaging, maintaining signal integrity with a touch of finesse, further solidifies its reputation as a preferred choice for applications demanding precision.

Variations in thickness and copper foil weight offer engineers a spectrum of choices, allowing customization to meet the unique demands of specific applications. The symphony of materials, from copper pathways to adhesive bonds, creates a PCB that not only excels in functionality but also exudes elegance through surface finishes like ENIG or immersion silver.

In essence, RT/duroid 5880 PCB is not just a circuit board; it is a technological symphony. Its adaptability to diverse circuit configurations, coupled with a stringent quality control crescendo, positions it as a reliable solution for those pushing the boundaries of high-frequency design. As we navigate through its FAQs, we discover a PCB that transcends expectations, offering a canvas for innovation in the dynamic landscape of advanced electronics. In a world where precision and reliability are paramount, RT/duroid 5880 PCB stands as a testament to the fusion of art and technology.Rogers 4835 PCB

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer