What is Ultra-Small Spacing High-Frequency PCBs?

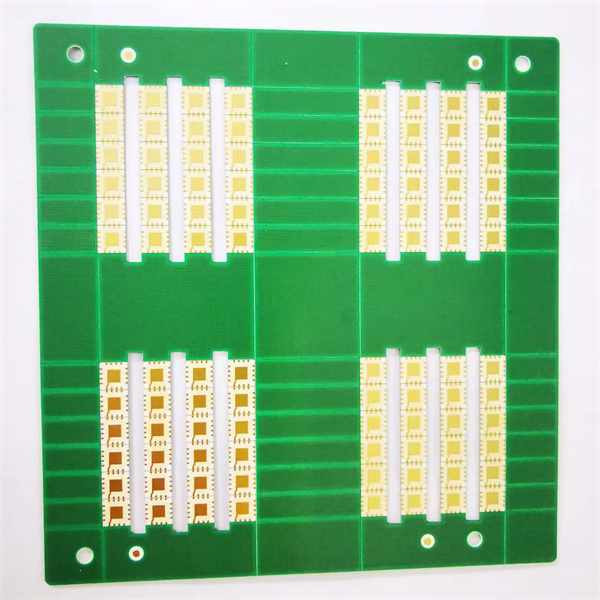

Ultra-small spacing high frequency PCB producer. the Package Substrate will be made with Showa Denko and Ajinomoto High speed materials. or other types high speed materials and high frequency materials. We will produce ultra-small pitch circuit boards or substrates according to the materials you require.

As we conclude our exploration, how evident is it that ultra-small gap high-speed PCBs act as catalysts for innovation in electronics? How do these advanced technologies redefine the landscape of electronic design, paving the way for a future where electronics are not just smaller but significantly faster and more efficient? Stay tuned for the continued evolution of ultra-small gap high-speed PCBs.

The emergence of ultra-small gap high-speed PCBs signifies a revolution in the field of electronics, exerting profound effects on electronic design and manufacturing. Here are several aspects of how they shape and innovate the future:

Balancing Size and Performance: Ultra-small gap high-speed PCBs make electronic devices smaller while achieving a significant boost in performance. This balance propels electronic devices to deliver more powerful functions within a smaller volume, opening up possibilities for innovation.

Higher Data Transfer Speeds: By reducing the gap in signal transmission paths, ultra-small gap high-speed PCBs effectively minimize signal propagation delays, resulting in higher data transfer speeds.This is vital for applications that demand real-time performance and swift data processing, such as communication devices and high-performance computing.

Improved Energy Efficiency: The combination of small size and high speed often comes with higher energy efficiency. Electronic devices can accomplish tasks more rapidly during data processing, reducing energy consumption. This contributes to meeting the growing demand for energy efficiency.

Multifunctional Integration: Ultra-small gap high-speed PCBs encourage more compact integration of electronic components, enabling multifunctionality. This integration allows devices to accommodate more functional units in a smaller space, enhancing device flexibility and diversity.

Rise of New Applications:Advancements in ultra-small gap high-speed PCB technology have led to the emergence of various applications, such as Internet of Things (IoT) devices, intelligent sensors, and autonomous driving systems. These innovations are pivotal in enhancing daily life, boosting industrial productivity, and fostering technological creativity.

In summary, ultra-small gap high-speed PCBs bring unprecedented opportunities to the field of electronics, driving the innovation and upgrade of electronic devices. In the future, we can expect to see smaller, faster, and more efficient electronic devices becoming the norm in daily life and industrial applications, providing robust support for technological development and societal progress.

What is the Core Function and Significance?

The core function and significance of ultra-small spacing high-frequency PCBs are closely tied to their specific requirements in the realm of high-frequency applications. Here are some aspects of their core function and significance:

Electrical Performance: Ultra-small spacing high-frequency PCBs are designed to provide excellent electrical performance, especially in the high-frequency range. This includes characteristics such as low loss, low crosstalk, and low propagation delay, ensuring accurate signal transmission and stability.

Signal Integrity: In high-frequency applications, signal integrity is crucial. The design of ultra-small spacing high-frequency PCBs helps reduce signal distortion and waveform distortion, ensuring that signals maintain their original characteristics during transmission.

EMI (Electromagnetic Interference) Control: In high-frequency environments, electromagnetic interference can negatively impact circuits. The design of ultra-small spacing high-frequency PCBs helps effectively control and reduce electromagnetic interference, enhancing the system’s resistance to interference.

Thermal Management: In high-frequency applications, devices may generate more heat. Ultra-small spacing high-frequency PCBs typically use special materials and heat dissipation designs to ensure effective thermal management, preventing excessively high temperatures from adversely affecting system performance.

Packaging Density: High-frequency applications often require integrating more functions and components into limited space. The design of ultra-small spacing high-frequency PCBs allows for higher packaging density, enabling the implementation of more complex circuit layouts in compact spaces.

High-frequency transmission line design in ultra-small spacing PCBs often incorporates specialized transmission lines like microstrip or coaxial lines. These designs aim to guarantee stable and low-loss signal transmission at elevated frequencies.

In conclusion, ultra-small spacing high-frequency PCBs are pivotal in high-frequency applications as they fulfill precise electrical, thermal, and mechanical criteria, ensuring the reliability and stability of systems. These characteristics prove indispensable in various fields including wireless communication, radar systems, high-speed data transmission, and beyond.

What Types Exist in the World of Ultra-Small Spacing High-Frequency PCBs?

In the realm of ultra-small spacing high-frequency PCBs, various types of circuit boards have been meticulously engineered to cater to specific application needs. Here are some common types of ultra-small spacing high-frequency PCBs:

Microstrip PCB:

Features: Microstrip PCBs transmit signals by creating a narrow conductor on the surface of the board. It is a common design suitable for relatively lower-frequency applications.

Applications: Used in RF (Radio Frequency) and microwave applications, such as communication systems, radar, and satellite communications.

Coaxial PCB:

Features: Coaxial PCBs utilize a coaxial structure where the signal line is enclosed within insulation and surrounded by an outer conductor. This provides effective shielding, reducing signal interference.

Applications: Widely used in high-frequency and microwave systems, such as antennas, measurement equipment, and medical devices.

Embedded Microstrip PCB:

Features: Embedded Microstrip PCBs incorporate conductors between layers to reduce electromagnetic radiation and enhance performance. This design is suitable for highly integrated systems.

Applications: Used in wireless communication, high-speed data transmission, and microwave applications.

Honeycomb PCB:

Features: Honeycomb PCBs employ a hexagonal honeycomb structure, offering improved mechanical stability and electromagnetic performance. This makes them suitable for applications demanding high reliability and stability.

Applications: Used in aerospace, military, and satellite applications where stringent requirements for mechanical and electromagnetic performance exist.

High-Frequency Multilayer PCB:

Features: High-Frequency Multilayer PCBs typically have high dielectric constants and low loss to ensure stability at high frequencies. They often consist of multiple layers, including ground and power layers, to provide enhanced electromagnetic performance.

Applications: Widely applied in RF, microwave, and millimeter-wave frequency range communication devices, antennas, and radar systems.

These types of ultra-small spacing high-frequency PCBs play crucial roles in the electronics industry, driving technological advancements in communication, healthcare, military, and other fields. Each type undergoes precise engineering to ensure optimal performance and reliability within specific frequency ranges.

How Do Ultra-Small Spacing High-Frequency PCBs Differ from Traditional PCBs?

Ultra-small spacing high-frequency PCBs differ significantly from traditional PCBs in terms of design, performance, and applications. Here are some key differences between them, particularly highlighting the advantages of advanced PCBs over traditional options, especially in high-frequency applications:

Design Differences:

Spacing and Layers: Ultra-small spacing high-frequency PCBs typically have smaller trace spacing and more layers. This aids in shortening the signal transmission path, mitigating signal loss, and enhancing the overall transmission performance of high-frequency signals.

Material Selection: Ultra-small spacing high-frequency PCBs commonly utilize advanced dielectric materials, like PTFE (polytetrafluoroethylene), to mitigate dielectric loss and minimize signal distortion.

Performance Differences:

High-Frequency Performance: Ultra-small spacing high-frequency PCBs exhibit superior performance in the high-frequency range as they can more effectively control signal transmission. This includes lower signal distortion, smaller coupling, and better impedance matching.

Signal Integrity: Due to smaller spacing and higher layers, ultra-small spacing high-frequency PCBs help maintain signal integrity, reducing signal reflection and crosstalk.

Application Differences:

High-Frequency Applications: Ultra-small spacing high-frequency PCBs are widely used in high-frequency applications such as radar systems, RF communication equipment, and satellite communication. They provide more reliable performance in these applications.

Medical Devices: Due to their high-performance characteristics, ultra-small spacing high-frequency PCBs are also suitable for some medical devices that demand high-quality signal transmission, such as medical imaging equipment.

Manufacturing and Cost:

Manufacturing Complexity: The manufacturing of ultra-small spacing high-frequency PCBs is relatively more complex, requiring higher precision processing and stricter quality control. This may result in higher manufacturing costs.

Application Requirements: In applications where performance requirements are not particularly high, traditional PCBs may still be a more economical choice as their manufacturing and design are relatively simpler.

In conclusion, ultra-small spacing high-frequency PCBs excel in high-frequency applications due to their enhanced performance achieved through optimized design, superior materials, and advanced manufacturing processes. Nevertheless, the selection between these and traditional PCBs should hinge upon the specific needs of the application and budgetary constraints.

Where Do Ultra-Small Spacing High-Frequency PCBs Find Applications and What Are Their Implications?

Ultra-small spacing high-frequency PCBs have found widespread applications in various fields due to their flexibility and performance advantages, making them a preferred choice in many high-tech industries. Here are some applications and implications of these PCBs in the miniaturization of electronic components and enhanced performance in high-frequency environments:

Medical Devices:

Applications: Ultra-small spacing high-frequency PCBs are extensively used in medical devices, especially in portable medical equipment and medical imaging systems. These devices require miniaturization for easy portability, and high-frequency PCBs provide the necessary electronic performance.

Impacts: The miniaturization of electronic components contributes to the lightweight and flexibility of medical devices, improving patient comfort. They play a crucial role in applications that require rapid response in medical settings.

Aerospace Technology:

Applications: The aerospace sector is witnessing a growing need for advanced electronic devices, and ultra-small spacing high-frequency PCBs are playing a pivotal role in radar, communication, and navigation systems.

Impacts:In the realm of aerospace applications, the significance of miniaturization and high-frequency capabilities in electronic devices cannot be overstated. These attributes not only result in a reduction of the system’s overall weight and volume but also contribute to heightened performance and reliability.

Communication Equipment:

Applications: Ultra-small spacing high-frequency PCBs are widely used in wireless communication devices, satellite communication systems, and base station equipment.

Impacts: In the realm of communication, the reduction in size of electronic components leads to the creation of more compact devices and an improved frequency response. This ultimately amplifies the efficiency and performance of communication systems.

Radio-Frequency Identification (RFID) Technology:

Applications: Ultra-small spacing high-frequency PCBs find extensive use in RFID tags and readers for logistics, inventory management, and identity recognition.

Impacts: Miniaturized electronic components contribute to the manufacturing of smaller RFID tags, enhancing stability and reading performance in various environmental conditions.

Ultra-small spacing high-frequency PCBs are not limited to the mentioned fields; they also play a crucial role in wireless sensor networks, military applications, automotive electronics, and various other sectors. A recurring theme in these applications is the need for electronic device miniaturization and high-frequency performance, underscoring the pivotal role that ultra-small spacing high-frequency PCBs play. Their effects encompass heightened system performance, decreased energy consumption, and increased stability and reliability.

What Constitutes the Main Structure and Production Technologies?

The main structure and production technologies of ultra-small spacing high-frequency PCBs encompass several key aspects:

Substrate Material: High-frequency PCBs typically employ materials with low dielectric constants and tangent losses to ensure optimal performance during signal transmission. Common materials include polytetrafluoroethylene (PTFE) and its composites, such as glass fiber-reinforced PTFE.

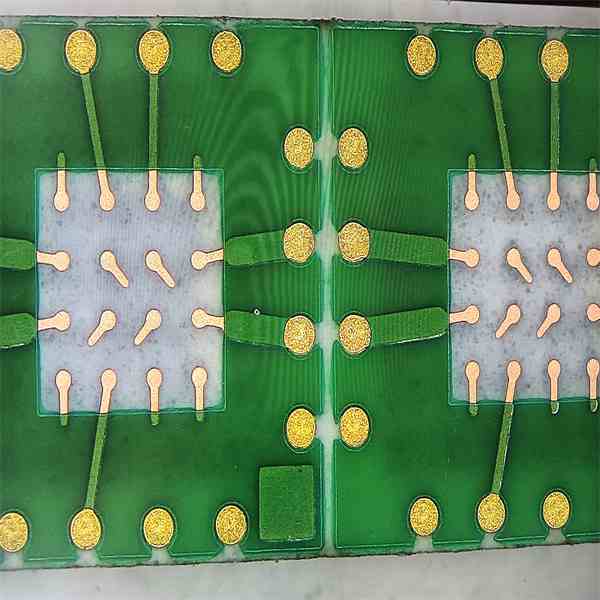

Conductor Layers: The conductor layers on the PCB usually use highly conductive metals like copper. In ultra-small spacing high-frequency PCBs, maintaining uniformity and good conductivity in the conductor layers is crucial to minimize signal loss during transmission.

Layer Stackup: High-frequency PCBs often adopt a multilayer stackup structure to accommodate more signal layers and ground planes. This helps reduce signal crosstalk and enhances overall performance.

Microstrip Lines and Impedance Control: Microstrip lines in ultra-small spacing high-frequency PCBs must be precisely designed to ensure the required impedance matching. High-precision control of line width and spacing is crucial and typically requires advanced manufacturing techniques.

Surface Treatment: The surface treatment of the PCB is essential for improving signal integrity. Common surface treatments include metallization, tin spraying, gold plating, etc., to enhance conductivity and corrosion resistance.

In the manufacturing process, a series of advanced technologies are employed, including:

Photolithography: Used to create fine lines and patterns, ensuring highly accurate conductive layers.

Chemical Etching: Used to remove unwanted metal to form the desired conductive shapes.

Multilayer Stacking Process: Involves layering different materials and conductor layers to construct a multilayer high-performance PCB.

Microfabrication Techniques: Include precision circuit etching, microstrip line fabrication, etc., to ensure stability in ultra-small spacing and high-frequency characteristics.

Achieving ultra-small spacing while maintaining optimal performance requires a high degree of precision during the manufacturing process. Control over parameters such as line width, line spacing, and stackup thickness needs to be at the micron level. This demands manufacturing processes equipped with highly precise equipment and rigorous quality control.

How Do Improved HDI Fabrication and Semi-Additive Methods Play a Role?

In the context of ultra-small spacing high-frequency PCBs, understanding how Improved High-Density Interconnect (HDI) fabrication and the semi-additive method contribute to pushing the boundaries of miniaturization is crucial. What role do these cutting-edge technologies play in the success of ultra-small spacing designs?

Firstly, let’s delve into what Improved High-Density Interconnect (HDI) fabrication and the semi-additive method entail.

Improved High-Density Interconnect (HDI) Fabrication:

Enhanced Interlayer Connection Density: HDI technology allows for more layers in a smaller space, thereby increasing the connection density. This is critical for ultra-small spacing designs as it enables more signal and power channels to traverse within a limited space.

Microvia Technology: HDI PCBs utilize microvia technology, permitting more signal channels to pass through different layers. This microvia technology is crucial for achieving highly complex interconnections in compact designs.

Fine-Line Technology: By employing fine-line manufacturing techniques, HDI allows for smaller trace widths and spacings, enabling the placement of more components on the PCB while reducing signal transmission delays.

Semi-Additive Method:

Precision Metal Deposition: The semi-additive method achieves highly customized metal layers by precisely depositing metal only in the required areas. This precision is crucial for maintaining signal integrity and reducing electromagnetic interference in ultra-small spacing designs.

Reduced Material Waste: In comparison to traditional full-additive methods, the semi-additive method reduces the need to add metal across the entire board, thereby minimizing material waste. This is crucial for efficiently utilizing space in small PCB designs.

In ultra-small spacing high-frequency PCB designs, the combination of these two technologies mutually drives the boundaries of miniaturization. They enable designers to achieve more functionalities and complex circuits within a confined space, enhancing performance while reducing the size and weight of the circuit board. Therefore, through Improved HDI fabrication and the semi-additive method, ultra-small spacing high-frequency PCBs can achieve more advanced and compact designs.

What Questions Surround Ultra-Small Spacing High-Frequency PCBs?

What is an ultra-small spacing high-frequency PCB?

An ultra-small spacing high-frequency PCB is a type of printed circuit board characterized by very close conductor spacing and high frequencies. This design is often used in high-frequency applications, such as RF (Radio Frequency) and millimeter-wave communication systems.

What are the primary applications of ultra-small spacing high-frequency PCBs?

Ultra-small spacing high-frequency PCBs find primary applications in scenarios requiring high frequencies and minimal signal distortion, including radar systems, communication devices, and satellite communications. The primary advantage of these PCBs is their ability to minimize signal attenuation and distortion during the transmission process.

What are the limitations of this design?

The production and troubleshooting processes for ultra-small spacing high-frequency PCB designs are intricate, primarily because of the minimal separation between conductors. This tight spacing can result in challenges such as signal crosstalk and electromagnetic interference..Additionally, material selection and the manufacturing process are crucial for maintaining high-frequency characteristics, potentially increasing costs.

How important is material selection for ultra-small spacing high-frequency PCBs?

The selection of materials is of paramount importance for these PCBs, as the dielectric constant, loss tangent, conductivity, and other properties of the material directly influence signal transmission and overall performance. Frequently utilized materials for high-frequency applications encompass PTFE (Polytetrafluoroethylene) and various others.

What is the impact of conductor spacing?

Small conductor spacing can increase signal transmission speed but also raises the risk of signal crosstalk. Therefore, a balance is needed in the design to meet the specific requirements of the application.

What are the design considerations for ultra-small spacing high-frequency PCBs?

Key design considerations include conductor spacing, material selection for interlayer insulation, ground plane design, impedance matching, and more. Balancing these factors is crucial to meet the requirements of specific applications while considering manufacturing costs and complexity.

What challenges exist in terms of cost for this design?

Manufacturing ultra-small spacing high-frequency PCBs typically requires higher precision in manufacturing processes and the use of more expensive materials, potentially making them relatively costly. Additionally, the complexity of design and debugging may contribute to increased costs.

What are the advantages of ultra-small spacing high-frequency PCBs compared to traditional PCBs?

Compared to traditional PCBs, ultra-small spacing high-frequency PCBs can offer higher signal transmission speeds, lower signal distortion, and superior high-frequency performance, making them an ideal choice for high-demand applications.

In Conclusion, What Does the Future Hold for Ultra-Small Spacing High-Frequency PCBs?

In conclusion, the advent of ultra-small spacing high-frequency PCBs signifies a transformative era in electronic manufacturing. As technology progresses, these specialized circuit boards are poised to play a pivotal role in shaping the future of smaller, more powerful, and efficient electronic devices.

To begin with, ultra-small spacing high-frequency PCBs are set to propel the miniaturization of electronic devices. Through the reduction in the dimensions of circuit boards and enhanced integration of components, devices can achieve a more compact form factor without compromising on high performance. This is especially vital for wearable devices, smart sensors, and other electronics with size constraints, resulting in increased portability, reduced weight, and enriched features.

Secondly, these high-frequency PCBs will support the advancement of communication technology. As 5G technology gains widespread acceptance and the need for higher frequencies grows, ultra-small spacing high-frequency PCBs are more aptly equipped to fulfill the performance criteria of communication devices. This proves crucial in enhancing data transfer speeds, minimizing latency, and accommodating a wider array of wireless connections.

Furthermore, the use of ultra-small spacing high-frequency PCBs will foster innovation in new electronic products. The design flexibility and superior performance of these circuit boards will encourage engineers to develop more advanced devices, such as virtual reality goggles, embedded artificial intelligence systems, and beyond. This will propel progress across the entire electronics industry, providing people with richer and more advanced technological experiences.

In summary, ultra-small spacing high-frequency PCBs represent a milestone in the field of electronic manufacturing, propelling electronic devices towards a future that is smaller, more powerful, and more efficient. Their applications will have profound impacts across various domains, laying the foundation for future technological innovations and advancements in electronic products.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer