Global Packaging Substrate Manufacturer. the best samllest bump pitch with 100um, the best Microtrace are 9um. and the smallest gap are 9um. Tost of the design are 15um to 30um trace and spacing.

Let’s explore the intriguing concept of “Global Packaging Substrate.” This term encompasses a diverse range of materials and technologies that come together to wrap up various products, ranging from sleek electronic gadgets to everyday essentials like snacks and medications. Think of it as the unsung hero, quietly providing the structural foundation for products, offering support, protection, and sometimes even incorporating smart features.

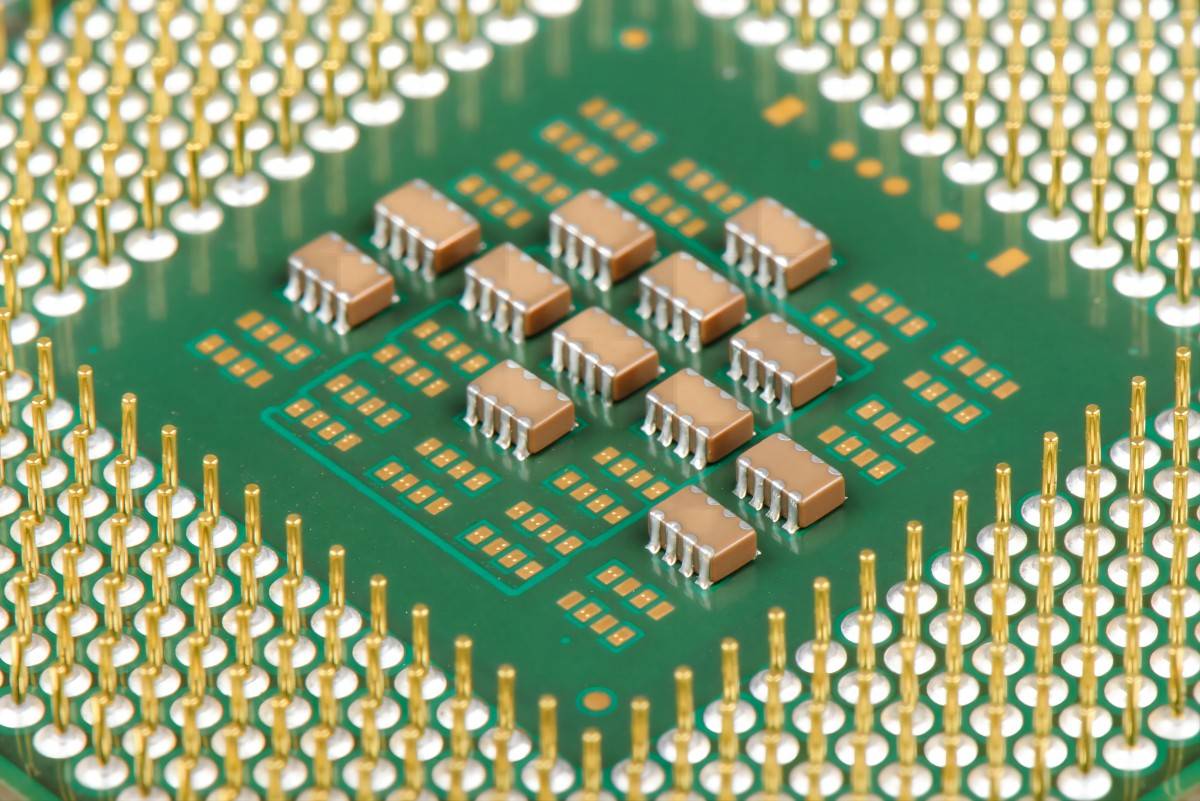

In the tech sphere, especially with components like chips and circuit boards, this packaging substrate takes on a pivotal role. It’s akin to the backstage crew ensuring a flawless performance – facilitating electrical connections, managing heat, and providing the essential physical support. Picture materials like the sophisticated FR4 (a high-tech fiberglass-reinforced epoxy blend), ceramics, metals, and flexible plastics, each bringing its own unique strengths based on the specific requirements of the task at hand.

Zooming out, “global packaging substrate” isn’t just industry jargon. It represents an expansive realm of materials, manufacturing techniques, and cutting-edge technologies collaborating to ensure products can traverse the globe. And it’s not just about functionality; it’s about doing it sustainably, cost-effectively, with top-notch performance, and in compliance with all necessary regulations. In essence, it’s about meeting the diverse needs of a vast and varied world.

What is the Function of Global Packaging Substrate?

The Global Packaging Substrate is like a chameleon, adapting to the specific needs of different products. Its roles are like a dynamic orchestra, playing various tunes:

Sturdy Foundation: Picture it as the rock-solid base that keeps products in shape, resilient against the bumps and jolts of handling, transportation, and storage.

Guardian of Goodness: It’s the superhero shield, warding off threats such as moisture, light, heat, and physical mishaps to keep products safe and sound.

Electrical Choreographer (for electronic devices): In the tech dance, the substrate takes center stage, conducting the intricate connections between circuits, semiconductors, and printed circuit boards for a flawless performance.

Cooling Maestro (for electronic devices): Playing the cool operator, it manages the heat, ensuring electronic components stay chill and perform at their best.

Feature Composer: Ever heard of packaging that does more than just hold stuff? The substrate can be customized to add features like RFID tags, anti-counterfeiting wizardry, or interactive elements, elevating the product experience.

Barrier Guardian: For products that need an extra layer of protection, the substrate steps up as the defender, shielding against gases, odors, and contaminants.

Aesthetic Artist: Beyond function, it contributes to the visual symphony of a product. Think graphics, colors, and textures – the packaging substrate is the artist painting the product’s visual story.

Green Guru: Keeping up with the eco-conscious vibe, packaging substrates can be eco-friendly champions, aligning with sustainability goals and regulations.

In a nutshell, the Global Packaging Substrate is a versatile performer, ensuring products not only stay intact but also dazzle on the global stage. It’s the unsung hero making sure every product’s unique melody is heard loud and clear.

What Are the Different Types of Global Packaging Substrate?

Enter the universe of global packaging substrates, a diverse array of types crafted to meet the unique demands of various applications. Let’s take a tour of this eclectic mix:

FR4 (Fiberglass-Reinforced Epoxy Laminate): Electronics enthusiasts swear by it. FR4, with its stellar electrical insulation properties, steals the show in the realm of printed circuit boards (PCBs).

Ceramics: When the heat is on, ceramics take the spotlight. Their prowess lies in applications where high thermal conductivity and unwavering mechanical stability are non-negotiable.

Metals: Aluminum and copper strut onto the stage, flaunting their excellent thermal conductivity. They play a crucial role in electronic packaging, ensuring components keep their cool.

Flexible Polymers: The acrobats of the substrate world, flexible polymers like polyimide and polyester, bend and twist to the needs of applications like flexible circuits and wearable electronics.

Paperboard and Cardboard: The down-to-earth heroes of consumer goods packaging, paperboard, and cardboard take center stage. They’re cost-effective, lightweight, and grace everything from food packaging to cosmetics.

Plastics: Versatility at its best, plastics such as PET and HDPE mold into different shapes, making them the go-to for various packaging requirements.

Foam: Soft but mighty, foam materials like expanded polystyrene and polyethylene cradle delicate items in protective packaging, ensuring a safe journey.

Composites: The fusion artists of the substrate world, composites blend different materials to create a symphony of strength and lightness, addressing specific needs with finesse.

Biodegradable Materials: Joining the sustainability parade, biodegradable substrates made from cornstarch or sugarcane offer eco-friendly alternatives, leaving a green footprint.

Metalized Films: Adding a touch of glamour, metalized films take the spotlight in flexible packaging, creating a barrier against moisture and gases with flair.

Picking the perfect packaging substrate is akin to selecting the right ensemble for a performance – it’s all about the nature of the product, desired features, and sustainability goals, ensuring a tailored and impressive show across diverse industries.

What is the Relationship Between Global Packaging Substrate and IC Packaging?

Consider the relationship between Global Packaging Substrate and IC Packaging as a synchronized performance in the intricate ballet of electronics. IC Packaging takes on the role of a protective partner for the integrated circuit (IC), while the Global Packaging Substrate serves as the versatile stage where this electronic ballet unfolds:

Electrical Symphony: Visualize the packaging substrate as the grand stage where the IC performs its electrical symphony. It facilitates the seamless flow of signals, allowing the IC to connect harmoniously within the broader electronic ensemble.

Thermal Pas de Deux: In a graceful dance of thermal management, the packaging substrate partners with the IC to maintain an optimal temperature. This elegant pas de deux ensures the IC performs without missing a beat, free from the overheating foxtrot.

Supporting Partner: The packaging substrate takes center stage as a reliable partner, offering robust support to the delicate IC. It shields the IC from external stresses, much like a protective dance partner, ensuring the performance maintains its durability and reliability.

Material Waltz: Material selection becomes a pivotal part of the dance routine. Imagine materials like FR4 and ceramics taking graceful steps, showcasing their electrical insulation properties, thermal conductivity, and mechanical strength in an elegant waltz.

Dimensions Dance: The size and form factor of the packaging substrate become part of the choreography. It’s a dance of dimensions, especially critical in applications where spatial constraints demand a perfectly coordinated routine.

Technological Rhapsody: As technology takes center stage, the partnership evolves in a rhythmic rhapsody. Innovations in IC packaging involve intricate moves within the packaging substrates, promising an ever-evolving electronic performance.

In essence, the dance between Global Packaging Substrate and IC Packaging is a beautifully orchestrated collaboration. The substrate provides the stage for the IC’s brilliance, offering support, connectivity, and protection. As the technological performance progresses, this partnership remains at the forefront of innovations in the dynamic world of electronics.

How Does Global Packaging Substrate Differ from Regular PCBs?

Delving into the distinction between Global Packaging Substrate and conventional Printed Circuit Boards (PCBs) requires exploring their diverse applications, functionalities, material choices, industry focuses, flexibility, and feature incorporations:

Application Scope:

Global Packaging Substrate: Casts a wide net, embracing a plethora of materials and technologies tailored for packaging a myriad of products globally. Its influence extends beyond electronics, making a mark in sectors like consumer goods and pharmaceuticals.

Regular PCBs: Specialize in shepherding electronic components, acting as the scaffold for electrical connections within electronic devices.

Functional Versatility:

Global Packaging Substrate: Masters the art of multi-functionality, serving as the backbone for structural support, protection, electrical connectivity, thermal management, and bespoke features catering to the packaged product.

Regular PCBs: Stick to their electronic roots, focusing on enabling seamless electrical connections and providing a robust mechanical foundation for electronic circuits.

Material Symphony:

Global Packaging Substrate: Dances across materials such as FR4, ceramics, metals, flexible polymers, and even paperboard, selecting the perfect ensemble to suit the unique demands of diverse products.

Regular PCBs: Often take center stage with materials like FR4, occasionally spicing things up with specialized materials such as Rogers or PTFE in high-frequency applications.

Industry Spotlight:

Global Packaging Substrate: Shines in a diverse array of industries, transcending the confines of electronics to touch realms like consumer goods and pharmaceuticals.

Regular PCBs: Hold their ground in the electronic arena, from everyday gadgets to heavy-duty industrial machinery.

Flexibility Ballet:

Global Packaging Substrate: Masters the art of flexibility, both in material choices and design, ensuring adaptability to the varying needs of different industries and products.

Regular PCBs: While flexible PCBs take a graceful bow for specific applications, their traditional FR4 counterparts typically maintain a rigid posture.

Feature Choreography:

Global Packaging Substrate: Takes the spotlight in a feature-rich performance, seamlessly incorporating elements like RFID tags, anti-counterfeiting measures, and interactive features into its repertoire.

Regular PCBs: Keep it essential, primarily focusing on the crucial role of providing connectivity for electronic components without indulging in additional features common in diverse packaging solutions.

In essence, Global Packaging Substrate emerges as a versatile performer, offering comprehensive packaging solutions across industries, while regular PCBs remain the steadfast anchors in the ever-evolving world of electronics.

What are the Main Structures and Production Technologies of Global Packaging Substrate?

Embarking on the exploration of Global Packaging Substrate reveals a captivating tapestry of structures and production technologies, finely tuned to the diverse needs across industries. Let’s delve into the distinct architectures and manufacturing methods shaping this vibrant landscape:

Structures:

Multilayered Marvels:

Description: Picture an intricate puzzle—multilayer structures intricately stack materials like FR4 or flexible polymers, creating a canvas for complex electronic circuits and fortifying structural resilience.

Application: Unveiled in advanced electronic packaging scenarios, where the need for intricate circuitry and heightened performance takes the spotlight.

Ceramic Fortresses:

Description: Step into the realm of robustness—structures fortified with ceramics like alumina or aluminum nitride, boasting unparalleled thermal conductivity and mechanical stability, ideal for applications demanding superior heat management.

Application: A common sight in high-power electronic devices, power modules, and environments requiring steadfast thermal control.

Metallic Guardians:

Description: Cloaked in metallic armor—structures adorned with aluminum or copper components offer not just durability but electromagnetic shielding, creating a haven for delicate electronic components.

Application: Thriving in aerospace, automotive, and military landscapes where shielding against electromagnetic interference is a non-negotiable.

Flexibility Unleashed:

Description: Embrace the fluidity—structures woven from flexible polymers like polyimide or polyester, bending and adapting to the needs of applications craving flexibility, such as wearable electronics.

Application: Flourishing in industries where flexibility and form factor are the stars of the show, gracing wearable devices and rollable displays.

Production Technologies:

PCB Symphony:

Description: A timeless overture—standard PCB manufacturing, etching copper layers onto FR4 substrates, composing the intricate melody of electronic circuits.

Application: The backbone of an orchestra of electronic devices, resonating in everything from household gadgets to industrial machinery.

Semiconductor Ballet:

Description: A dance of precision—advanced packaging technologies delicately encapsulate semiconductor devices, employing materials like ceramics or organic substrates for protection and enhanced functionality.

Application: The choreography behind the creation of integrated circuits (ICs), microprocessors, and the technological ballet.

3D Pinnacle:

Description: Ascend to new dimensions—3D packaging techniques elevate components vertically, orchestrating a symphony of spatial optimization and enhanced system performance.

Application: Leading the way in advanced electronic systems, data centers, and the grand stage of high-performance computing.

Additive Alchemy (3D Printing):

Description: Crafting layer by layer—a narrative of additive manufacturing techniques sculpting intricate substrate structures, offering the freedom of design flexibility and customization.

Application: Unfolding in realms of prototyping and specialized applications, where the traditional playbook finds its boundaries.

Flexible Harmony (Flexible Hybrid Electronics – FHE):

Description: A delicate fusion of rigidity and flexibility—FHE gracefully marries printed electronics on flexible substrates, composing a melody of conformal and lightweight designs.

Application: Emerging as a virtuoso in wearable technology, medical devices, and the avant-garde field of flexible sensors.

In essence, the symphonic journey of Global Packaging Substrate unfolds through an array of structures and production technologies, each playing a unique note in the grand composition of industries and innovations.

Frequently Asked Questions (FAQs)

What exactly is Global Packaging Substrate?

Global Packaging Substrate stands as the versatile backbone of packaging solutions worldwide. It goes beyond the conventional, offering the base for structural support, protection, and a touch of innovation in various products.

Where does Global Packaging Substrate make its mark?

The impact of Global Packaging Substrate is felt across the board – from electronic devices to everyday consumer goods, pharmaceuticals, and even the contents of your pantry. Its role extends to shaping diverse packaging solutions in various industries.

How does it differ from your regular PCBs?

Think of Global Packaging Substrate as the sophisticated older sibling. While regular PCBs stick to their electronic connectivity gig, Global Packaging Substrate steals the spotlight by embracing a broader spectrum. It’s not just about circuits; it’s about support, protection, and flexibility.

What materials take center stage in Global Packaging Substrate?

The material lineup reads like a star-studded cast – FR4, ceramics, metals, flexible polymers, and even paperboard. Each material is carefully selected to match the unique demands of the product and its intended application.

How does it contribute to the grand performance of electronic devices?

In the world of electronic devices, Global Packaging Substrate takes on a multi-talented role – providing electrical connectivity, managing thermal intricacies, and offering the structural support that keeps components like integrated circuits in the spotlight.

Any fresh trends making waves in Global Packaging Substrate?

Brace yourself for the avant-garde! Trends include the dance of flexible hybrid electronics (FHE), the 3D packaging extravaganza, and the artistry of additive manufacturing (3D printing), introducing customized and cutting-edge packaging solutions.

How does Global Packaging Substrate waltz with regulatory compliance?

Compliance is the dance partner that can’t be ignored. Global Packaging Substrate gracefully aligns with regulatory standards, ensuring product safety, environmental responsibility, and compliance with industry-specific regulations.

Are there any cool innovations related to smart packaging in Global Packaging Substrate?

Absolutely! Picture Global Packaging Substrate as the canvas for innovation, featuring smart elements like RFID tags, sensors, and interactive features – transforming packaging into an intelligent and engaging experience.

Which industries get a front-row seat to the benefits of Global Packaging Substrate advancements?

The VIP list includes electronics, healthcare, food and beverage, pharmaceuticals, and the vast arena of consumer goods. Global Packaging Substrate takes center stage in shaping the future of packaging across diverse industries.

Conclusion

In wrapping up our exploration, Global Packaging Substrate emerges as the linchpin in the intricate dance of packaging technologies. Going beyond the conventional realm of Printed Circuit Boards (PCBs), it paints a canvas that spans industries, each stroke revealing a versatile material symphony.

The materials employed – be it the stalwart FR4, the resilient ceramics, or the flexible polymers – mirror a palette carefully chosen to meet the distinct demands of various applications. The collaboration between Global Packaging Substrate and electronic devices is nothing short of a choreographed performance, where ICs and PCBs take center stage, showcasing the substrate’s prowess in ensuring seamless connectivity, efficient thermal management, and robust mechanical support.

In the pursuit of sustainability, Global Packaging Substrate becomes a conscientious player, embracing eco-friendly materials and production processes. Compliance with regulatory standards becomes not just a necessity but a commitment to responsible practices.

The ever-evolving trends in this arena unfold a narrative of innovation – from the fluidity of flexible hybrid electronics to the vertical ascension of 3D packaging techniques and the additive manufacturing revolution. Structures like multilayered marvels and ceramic fortresses become not just components but artistic expressions of adaptability and resilience.

As we delve into the Frequently Asked Questions (FAQs), the tapestry of Global Packaging Substrate unfurls, answering queries about its applications, sustainability initiatives, and the pulse of emerging trends. It becomes evident that this isn’t a static field but a dynamic force shaping the packaging landscape globally.

In summary, Global Packaging Substrate takes its bow as a nexus of innovation, sustainability, and adaptability. It is not merely a supporting cast but a protagonist influencing how products are enveloped, safeguarded, and introduced in the ever-shifting global panorama.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer