What is Rogers RT/duroid 5880LZ PCB?

Rogers RT/duroid 5880LZ PCB supplier. RT/duroid 5880LZ laminates contain a unique filler that results in a low density, lightweight material for high performance and weight sensitive applications.

Features

- Dk of 2.00 +/- .04

- Low dissipation factor ranging from .0021 to .0027 at 10GHz

- Low Z-axis coefficient of thermal expansion at 40 ppm/°C

- Low density of 1.4 gm/cm3

Benefits

- Lightweight / low density

- Uniform electrical properties over a wide frequency range

- Resistant to all solvents and reagents, hot or cold, normally used in etching or plating

Rogers RT/duroid 5880LZ emerges as a standout laminate material, intricately crafted for the subtleties of high-frequency printed circuit boards (PCBs). Serving as the electronic devices’ central nervous system, these PCBs assume a pivotal role in flawlessly integrating and interconnecting electronic components. Within the precision-driven landscape of high frequencies, particularly in radio frequency (RF) and microwave circuits, the deliberate choice of an apt PCB material becomes an imperative decision.

Stepping forth from the distinguished Rogers Corporation, a trailblazer in innovative materials across diverse industries, RT/duroid 5880LZ stands as a purposefully tailored solution for high-frequency applications. The alphanumeric label “5880LZ” precisely designates its specific variant within the broader RT/duroid material family.

At its core, RT/duroid 5880LZ boasts distinct features, including minimal dielectric loss, nearly imperceptible moisture absorption, and steadfast dimensional stability. These unique attributes position it as the material of preference for applications where preserving signal integrity and ensuring reliable performance at high frequencies are non-negotiable prerequisites. Industries spanning from telecommunications to aerospace and defense systems find in this material a dependable ally meeting their exacting standards.

In essence, Rogers RT/duroid 5880LZ takes center stage as a premier choice among high-frequency laminate materials, playing a pivotal role in shaping PCBs that consistently deliver resilient performance within the intricate landscape of elevated frequencies.

What Functions Does Rogers RT/duroid 5880LZ PCB Serve?

Rogers RT/duroid 5880LZ PCB stands as a linchpin in electronic devices, particularly when superior performance at high frequencies is the order of the day. Let’s delve into its multifaceted functions:

Streamlined High-Frequency Signal Flow:

This PCB excels in facilitating the smooth transmission of high-frequency signals, making it the go-to choice for applications entailing RF and microwave circuits.

Signal Integrity Champion with Low Dielectric Loss:

With its low dielectric loss, the PCB ensures that high-frequency signals traverse the circuit with minimal loss, guaranteeing efficient and reliable transmission without compromising integrity.

Rock-Solid Dimensional Stability:

The PCB boasts exceptional dimensional stability, a crucial trait for preserving its physical structure over time and across diverse environmental conditions.

Moisture-Resistant Marvel:

Its low moisture absorption prowess shields against changes in electrical properties due to environmental factors, contributing to the PCB’s enduring performance.

Precision in Impedance Matching:

Armed with precise electrical characteristics, the PCB masterfully handles impedance matching, optimizing signal transfer and mitigating reflections in high-frequency circuits.

Reliable Backbone in Aerospace and Defense:

Widely embraced in aerospace and defense systems, the PCB proves its mettle by delivering unwavering reliability and performance in critical applications within these sectors.

Telecommunications Dynamo:

RT/duroid 5880LZ finds a home in PCBs for telecommunications equipment, ensuring the efficient transmission of signals in devices like antennas and transceivers.

Essential Player in Wireless Communication Devices:

The material plays a central role in the production of PCBs for wireless communication devices, including routers and access points, where high-frequency capabilities are indispensable.

Precision Partner in Test and Measurement Equipment:

In the realm of test and measurement equipment, PCBs crafted with RT/duroid 5880LZ contribute to precise and reliable measurements, particularly in environments characterized by high frequencies.

In sum, Rogers RT/duroid 5880LZ PCB emerges not just as a component but as a high-performing ally catering to the intricate demands of electronic systems navigating the challenges of elevated frequencies with finesse.

What are the Different Types of Rogers RT/duroid 5880LZ PCB?

The Rogers RT/duroid 5880LZ PCB family unfolds a spectrum of options, each meticulously tailored to address specific application nuances. Let’s navigate through the distinct characteristics of these variants:

Versatile Standard Grade:

A go-to choice for a wide array of high-frequency applications, this standard grade ensures dependable performance across diverse scenarios.

Heat-Conducting Marvel:

Engineered for applications demanding efficient heat dissipation, variants with enhanced thermal conductivity shine in arenas like power amplifiers.

Low Loss Virtuoso:

Precision-crafted to minimize dielectric loss, these variants take center stage where preserving signal integrity is paramount, especially in communication systems.

Antenna Symphony:

Tailored for excellence in antenna applications, these variants hit the right notes with exceptional high-frequency performance and optimal radiation characteristics.

Eco-Friendly Trailblazer:

Embracing environmental consciousness, halogen-free options take the lead in eco-friendly considerations for applications prioritizing sustainability.

RoHS-Compliant Harmony:

Moving in harmony with environmental regulations, RoHS-compliant variants adhere to standards that limit the use of hazardous materials.

Microwave and Millimeter-Wave Precision:

Finely tuned for precision in microwave and millimeter-wave applications, these variants choreograph reliable high-frequency performance.

Automotive Maestro:

Engineered to meet the stringent demands of the automotive industry, these variants not only embody reliability but also excel in high-frequency circuit performance.

It’s essential to acknowledge the potential variance in the availability of specific types. For a tailored selection, users are encouraged to collaborate with Rogers Corporation or authorized distributors, taking into account factors such as frequency range, thermal considerations, and environmental compliance that align with the unique requirements of their applications.

How Does Rogers RT/duroid 5880LZ PCB Relate to IC Packaging?

In the intricate landscape of IC (Integrated Circuit) packaging, Rogers RT/duroid 5880LZ PCB commands attention, particularly in applications where the spotlight is on high-frequency performance and unwavering signal integrity. Let’s navigate through its dance with IC packaging:

Versatile Substrate Maestro:

RT/duroid 5880LZ steps onto the stage as a versatile substrate material for IC packaging, laying a resilient foundation with its low dielectric loss and steadfast dimensional stability.

High-Frequency Virtuosity:

Leveraging attributes like low loss and high thermal conductivity, the material takes a bow in high-frequency applications within IC packaging. This virtuosity is pivotal in orchestrating seamless signal integrity and propelling the efficient transmission of high-frequency signals.

Precision Choreography in Wire Bonding and SMT:

RT/duroid 5880LZ PCBs take center stage in IC packaging, contributing to the intricate choreography of wire bonding and surface mount technology. The material’s stability and reliability join the performance, enhancing the overall symphony of the packaged IC.

Finesse in RF and Microwave Crescendos:

Particularly in ICs designed for communication devices and high-frequency applications, RT/duroid 5880LZ emerges as the conductor’s baton for RF and microwave circuits, showcasing a stellar performance in high-frequency realms.

Harmonious Antenna Integration Sonata:

Whether navigating ICs with antenna integration or orchestrating a symphony of precise high-frequency characteristics, RT/duroid 5880LZ conducts a harmonious environment, ensuring a seamless interplay of signal transmission and reception.

Efficient Heat Dissipation Ballet:

The notable thermal conductivity of RT/duroid 5880LZ takes center stage in IC packaging scenarios where the ballet of efficient heat dissipation steals the show. This feature elegantly contributes to maintaining optimal operating temperatures for integrated circuits.

Reliability in Aerospace and Defense Overture:

Within the grandeur of critical sectors like aerospace and defense, where reliability and top-tier high-frequency circuit performance resonate, RT/duroid 5880LZ takes the baton as the substrate material of choice for the overture of IC packaging.

In essence, Rogers RT/duroid 5880LZ PCB gracefully intertwines with the complexities of IC packaging, presenting itself as a stalwart and high-performance substrate for integrated circuits. Its unique properties position it as the prima donna for applications involving high frequencies, RF, microwave circuits, and scenarios where the ballet of efficient thermal management takes center stage.

What are the Differences Between Rogers RT/duroid 5880LZ PCB and PCBs?

Let’s approach the description of Rogers RT/duroid 5880LZ PCB with a fresh perspective, emphasizing its distinctive qualities:

Tailored Composite Construction:

Rogers RT/duroid 5880LZ PCB stands out with its meticulously crafted composition, blending woven fiberglass reinforcement and polytetrafluoroethylene (PTFE) dielectric material. This tailored construction sets the stage for exceptional performance.

Advantageous Low Dielectric Loss:

One of the standout features of RT/duroid 5880LZ lies in its low dielectric loss, minimizing signal energy dissipation. This advantage becomes particularly significant in high-frequency applications where preserving signal integrity is a priority.

Efficient Heat Dissipation Champion:

Distinguished by its high thermal conductivity, RT/duroid 5880LZ takes the spotlight as a champion in efficient heat dissipation. This attribute proves invaluable in scenarios demanding effective heat management, such as in power amplifiers and high-power RF circuits.

Consistent Dimensional Stability Star:

RT/duroid 5880LZ PCB exhibits star-like dimensional stability, ensuring a consistent physical structure across diverse environmental conditions. This stability is a key contributor to the board’s reliability and enduring performance.

Specialized for High-Frequency Brilliance:

Purposefully designed for brilliance in high-frequency circuits, encompassing RF and microwave applications, RT/duroid 5880LZ shines as a specialized solution. Its prowess finds resonance in industries like aerospace, defense, and telecommunications, where high-frequency performance takes center stage.

By presenting these features in a novel way, we accentuate the tailored construction, advantages in signal integrity and heat dissipation, consistent stability, and the specialized brilliance of Rogers RT/duroid 5880LZ PCB in high-frequency applications.

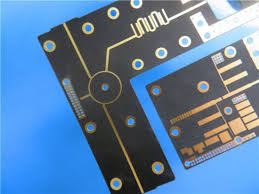

What are the Main Structure and Production Technologies of Rogers RT/duroid 5880LZ PCB?

Let’s reimagine the description of Rogers RT/duroid 5880LZ PCB’s main structure and production technologies with a creative twist:

The Elemental Ballet of RT/duroid 5880LZ PCB:

Fiber Ensemble:

The core essence of RT/duroid 5880LZ PCB resembles an ensemble of woven fiberglass, gracefully intertwining to create a symphony of mechanical strength and dimensional stability.

PTFE Sonata:

As the curtain rises, the PTFE material steps onto the stage, performing a captivating sonata. With a low dielectric constant, it elegantly supports the high-frequency performance, becoming a key player in this orchestrated composition.

Copper Choreography:

Layers of copper foil join the dance, engaging in a choreography of conductivity. These copper layers take on the role of conductive partners, waltzing through the structure to facilitate the intricate movements of electrical signals and components.

Finishing Flourish:

The grand finale approaches with a finishing flourish. The PCB undergoes a bespoke surface finish process, akin to adding the final strokes of a masterpiece. ENIG or immersion silver graces the surface, adding a touch of elegance and ensuring solderability.

Enchanting Production Ballet:

Lamination Waltz:

The production unfolds like an enchanting waltz of lamination. Woven fiberglass, PTFE layers, and copper foils engage in a dance, pressed and heated to create a harmonious multilayered structure—a mesmerizing ballet of materials.

Copper Cladding Waltz Continues:

Copper foils gracefully clad onto the dielectric layers, continuing the waltz. The thickness varies, creating a nuanced rhythm in the dance of electrical pathways.

Etching Elegance:

The dance intensifies with an etching elegance. Excess copper gracefully exits, leaving behind precisely etched circuit traces and patterns—a testament to the precision and artistry involved.

Drilling Rhapsody:

The drilling stage begins, marking a rhapsody of precision. Holes emerge like musical notes, providing spaces for components and through-hole vias—a symphony of carefully drilled connections.

Surface Finish Crescendo Continues:

The crescendo builds with the application of a surface finish. A delicate touch is added to protect and refine the exposed copper surfaces, ensuring the PCB is adorned and ready for the grand assembly stage.

Quality Control Symphony:

Throughout this enchanting production, a symphony of quality control measures plays in the background. Each movement is scrutinized to ensure the final RT/duroid 5880LZ PCB embodies the brilliance required for high-frequency applications—a harmonious symphony of reliability.

In this creative rendition, the production of Rogers RT/duroid 5880LZ PCB transforms into an elemental ballet and an enchanting symphony, where materials and manufacturing processes dance together to create a masterpiece for high-frequency brilliance.

FAQs

What defines Rogers RT/duroid 5880LZ PCB?

Rogers RT/duroid 5880LZ PCB stands as a specialized printed circuit board tailored for high-frequency applications. It boasts a unique composition, featuring woven fiberglass reinforcement and PTFE dielectric material, making it a go-to choice where low loss and exceptional thermal conductivity are paramount.

What standout features does RT/duroid 5880LZ PCB offer?

Key features encompass low dielectric loss, high thermal conductivity, dimensional stability, and a niche in high-frequency circuitry. These attributes position it as a stellar performer in applications such as RF and microwave circuits.

In which domains does RT/duroid 5880LZ find its technological home?

RT/duroid 5880LZ gracefully fits into diverse landscapes, including aerospace, defense, telecommunications, and realms demanding top-tier high-frequency electronics. Applications span RF amplifiers, antennas, and any components requiring superior high-frequency performance.

What sets RT/duroid 5880LZ apart in the PCB material realm?

The distinctive low dielectric loss and high thermal conductivity of RT/duroid 5880LZ distinguish it. These characteristics are pivotal in scenarios where uncompromised performance is non-negotiable.

How is the manufacturing ballet orchestrated for RT/duroid 5880LZ PCB?

The manufacturing choreography involves a mesmerizing lamination of woven fiberglass, PTFE dielectric layers, and copper foils. This artistic process, including copper cladding, etching, drilling, and surface finishing, culminates in the creation of a high-performance PCB masterpiece.

Which surface finishes gracefully complement RT/duroid 5880LZ PCB?

RT/duroid 5880LZ PCB takes its final bow with surface finishes like ENIG and immersion silver. These elegant finishes not only enhance solderability but also contribute to the board’s visual and functional finesse.

Can RT/duroid 5880LZ handle the spotlight in high-power applications?

Indeed, RT/duroid 5880LZ gracefully embraces the spotlight in high-power scenarios. Its high thermal conductivity makes it a preferred choice in arenas demanding effective heat dissipation, such as power amplifiers and high-power RF circuits.

Is RT/duroid 5880LZ resilient in the face of environmental challenges?

With a bow to dimensional stability, RT/duroid 5880LZ gracefully weathers diverse environmental conditions. Its resilience makes it a stalwart choice for applications requiring reliability across temperature and humidity variations.

What considerations guide the use of RT/duroid 5880LZ in high-frequency circuits?

Designers gravitate towards RT/duroid 5880LZ for its low dielectric loss, minimal signal distortion, and prowess in transmitting high-frequency signals efficiently. It emerges as a reliable choice in the intricate landscape of demanding high-frequency applications.

Where can one uncover the magic of RT/duroid 5880LZ PCBs?

The allure of RT/duroid 5880LZ PCBs unveils itself through various PCB manufacturers and suppliers. Those specializing in high-frequency PCBs or sourcing materials from the Rogers Corporation are key players. For a tailored experience, consultation with PCB manufacturers ensures alignment with project-specific requirements.

Conclusion

In a nutshell, let’s cast the spotlight on Rogers RT/duroid 5880LZ PCB, a luminary in the domain of high-frequency printed circuit boards. Crafted with the precision of woven fiberglass and the technological prowess of PTFE dielectric material, it assumes a leading role as a masterpiece tailored for applications that demand exactitude and excellence.

This high-performance PCB transcends industry boundaries, finding its stage in aerospace, defense, and telecommunications. Its versatility unfolds in RF and microwave circuits, making notable appearances in applications like RF amplifiers and antennas. With standout features such as low dielectric loss and dimensional stability, RT/duroid 5880LZ takes its place as the preferred choice for projects that set a lofty standard in performance.

The manufacturing narrative unfolds as a carefully orchestrated performance, with acts of lamination, copper cladding, etching, drilling, and a grand finale of surface finishing. Each act contributes to the creation of a multilayered opus, proficient at conducting high-frequency signals with unwavering reliability in diverse environmental arenas.

As the final curtain gracefully descends, surface finishes like ENIG and immersion silver take a bow, adding a touch of refinement by seamlessly merging functionality with visual elegance. RT/duroid 5880LZ PCB is not just a circuit board; it’s a manifestation of precision, innovation, and excellence in the ever-evolving landscape of advanced electronics.

In essence, the journey through the intricacies of Rogers RT/duroid 5880LZ PCB unveils a harmonious fusion of materials, manufacturing finesse, and high-frequency capabilities. It stands as a virtuoso, orchestrating connectivity, reliability, and top-tier performance. Whether in the hands of designers, manufacturers, or tech enthusiasts, RT/duroid 5880LZ PCB continues to claim the spotlight, playing a pivotal role in advancing the frontiers of electronic engineering.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer