Wire Bonding BGA substrates Manufacturer

Wire Bonding BGA substrates Manufacturer, BGA/IC package substrates, To usd the BT materials, ABF materials, Rogers materials, and other High speed and high frequency materials for BGA/IC substrate production from 2 layer to 22 layers.

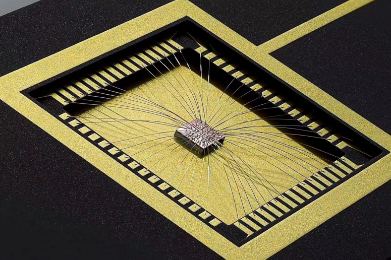

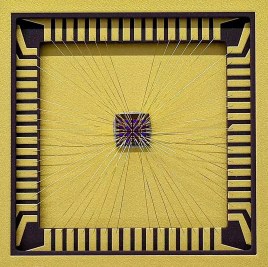

Wire bonding BGA substrates are a crucial packaging technology used in semiconductor devices, facilitating high-density interconnections between integrated circuits and the external circuitry. In this process, thin wires, typically made of gold or aluminum, are meticulously bonded between the electrical pads on the IC chip and the corresponding pads on the substrate. This bonding is achieved through the application of heat, pressure, and ultrasonic energy, ensuring reliable electrical connections. Wire bonding BGA substrates offer numerous advantages, including cost-effectiveness, flexibility in design, and suitability for applications with space constraints and high pin counts. The substrates are meticulously fabricated using advanced manufacturing processes, incorporating materials such as FR-4, ceramics, laminates, or metal-core PCBs to meet diverse application requirements. With their ability to deliver both reliability and performance, wire bonding BGA substrates play a pivotal role in various semiconductor applications, from consumer electronics to automotive and industrial sectors.

What are Wire Bonding BGA Substrates?

Wire bonding BGA substrates refer to a specific type of packaging technology used in semiconductor devices, particularly in Ball Grid Array (BGA) packages. BGA packages are widely used in integrated circuits (ICs) where high-density interconnection is required.

In BGA packaging, the integrated circuit is mounted on a substrate, which is typically a flat piece of material, such as ceramic or laminate, that provides electrical connections between the chip and the external circuitry. Wire bonding is one of the methods used to establish these connections.

Wire bonding involves using thin wires, typically made of gold or aluminum, to connect the electrical pads on the surface of the integrated circuit chip to the corresponding pads on the substrate. These wires are typically very fine, on the order of micrometers in diameter, and are bonded to the pads using heat, pressure, and ultrasonic energy.

Wire bonding BGA substrates specifically refer to BGA packages where wire bonding is used as the primary method for making these electrical connections. This technique is often chosen for its reliability and cost-effectiveness, especially for applications where high-density interconnection is required but the complexity or cost of other methods, such as flip-chip bonding, is prohibitive.

Wire Bonding BGA substrates

What are the Design Guidelines for Wire Bonding BGA Substrates?

Design guidelines for wire bonding BGA substrates are crucial to ensure proper functionality, reliability, and manufacturability of the integrated circuits. Here are some key design guidelines:

- Pad Placement and Size: Ensure that the pads on the integrated circuit chip and the substrate are properly aligned and sized to accommodate wire bonding. The spacing between pads should be sufficient to prevent short circuits during wire bonding.

- Pad Pitch: The pitch, or spacing, between adjacent pads should be carefully chosen to match the wire bonding capabilities and equipment. Typically, finer pitches allow for higher pin counts but may require specialized wire bonding equipment.

- Pad Material: Use materials for pads that are suitable for wire bonding, such as gold or aluminum. These materials should provide good bondability and reliability.

- Pad Metallization: Proper metallization of the pads is essential to ensure good adhesion and electrical conductivity during wire bonding. Common metallization methods include nickel/gold (Ni/Au) or aluminum.

- Wire Loop Height and Length: Maintain proper wire loop height and length to ensure adequate clearance and avoid interference with neighboring wires or components. Improper loop height can lead to wire shorts or open circuits.

- Bonding Diagram:Create a detailed bonding diagram that specifies the bonding sequence, wire sizes, bond locations, and loop profiles. This helps ensure consistency and accuracy during the wire bonding process.

- Substrate Material and Thickness: Choose substrate materials that provide good mechanical strength, thermal conductivity, and electrical properties. Common substrate materials include FR-4, ceramics, and laminates. The substrate thickness should be sufficient to support the wire bonding process and provide mechanical stability.

- Die Attach: Ensure proper die attach techniques to securely bond the integrated circuit chip to the substrate. This helps prevent chip movement or delamination during wire bonding.

- Thermal Management: Consider thermal management techniques to dissipate heat generated during the wire bonding process. Excessive heat can affect bond quality and reliability.

- Testing and Inspection: Implement testing and inspection processes to verify the integrity of wire bonds and detect any defects or failures early in the manufacturing process.

By following these design guidelines, engineers can optimize the wire bonding BGA substrate design for performance, reliability, and manufacturability.

Wire Bonding BGA substrates

What is the Wire Bonding BGA Substrates Fabrication Process?

The fabrication process for wire bonding BGA (Ball Grid Array) substrates involves several steps to create the substrate with the necessary pads and interconnections for wire bonding. Here’s a generalized overview of the process:

- Substrate Preparation:

– Selection of substrate material: Choose a suitable substrate material such as FR-4, ceramics, or laminates based on the specific requirements of the application.

– Substrate cleaning: Clean the substrate surface to remove any contaminants that could affect the bonding process.

- Metallization:

– Deposition of metal layers: Apply thin layers of metal (typically copper) onto the substrate surface using techniques like sputtering or electroplating.

– Photolithography: Use photolithography to define the pattern of pads and traces on the substrate. A photoresist layer is applied, exposed to UV light through a photomask, developed to remove the unexposed areas, and then the exposed metal is etched away to leave behind the desired pattern.

- Die Attach:

– Adhesive application: Apply a die attach adhesive to the substrate surface in the designated area where the integrated circuit (IC) chip will be mounted.

– Placement of IC chip: Place the IC chip onto the adhesive layer, ensuring proper alignment with the substrate pads.

- Wire Bonding:

– Wire bonding setup: Set up the wire bonding equipment, including the wire bonding machine and ultrasonic bonding tool.

– Wire selection: Choose the appropriate wire material (e.g., gold or aluminum) and diameter based on the application requirements.

– Wire bonding process: Use the wire bonding machine to bond the wires between the pads on the IC chip and the corresponding pads on the substrate. This process typically involves applying heat, pressure, and ultrasonic energy to create a reliable electrical connection.

- Encapsulation:

– Encapsulant application: Apply an encapsulant material (e.g., epoxy resin) over the wire bonds and IC chip to protect them from environmental factors such as moisture, mechanical stress, and thermal cycling.

– Curing: Cure the encapsulant material to harden it and ensure proper adhesion to the substrate and IC chip.

- Testing and Inspection:

– Electrical testing: Perform electrical tests to verify the functionality and integrity of the wire bonds and IC chip.

– Visual inspection: Inspect the substrate and wire bonds visually for any defects, such as wire shorts, open circuits, or voids in the encapsulant.

- Trim and Form (if necessary):

– Trim excess wire: Trim any excess wire lengths to ensure uniformity and optimize the overall package size.

– Forming: Form the leads or terminals of the substrate according to the desired configuration (e.g., flat leads, gull-wing leads) for surface mounting onto a printed circuit board (PCB).

- Packaging and Shipping:

– Package the wire bonding BGA substrates in protective materials or trays to prevent damage during shipping and handling.

– Labeling: Label the packages with relevant information such as part number, date code, and manufacturing batch for traceability.

By following these fabrication steps, manufacturers can produce wire bonding BGA substrates that meet the required specifications for various semiconductor applications.

How do you Manufacture Wire Bonding BGA Substrates?

Manufacturing wire bonding BGA (Ball Grid Array) substrates involves a series of steps to fabricate the substrate and then assemble the integrated circuit (IC) chips onto it using wire bonding technology. Here’s a detailed outline of the manufacturing process:

- Design and Substrate Fabrication:

– Design the layout of the substrate, including the placement of pads, traces, and any additional features required for wire bonding.

– Select a suitable substrate material such as FR-4, ceramics, or laminates based on the application requirements.

– Fabricate the substrate using processes like metallization, photolithography, and etching to create the desired pattern of pads and traces on the substrate surface.

- Die Attach:

– Apply a die attach adhesive to the substrate surface in the designated area where the IC chip will be mounted.

– Place the IC chips onto the adhesive layer, ensuring proper alignment with the substrate pads.

- Wire Bonding:

– Set up the wire bonding equipment, including the wire bonding machine and ultrasonic bonding tool.

– Choose the appropriate wire material (e.g., gold or aluminum) and diameter based on the application requirements.

– Use the wire bonding machine to bond the wires between the pads on the IC chips and the corresponding pads on the substrate. This process involves applying heat, pressure, and ultrasonic energy to create reliable electrical connections.

- Encapsulation:

– Apply an encapsulant material (e.g., epoxy resin) over the wire bonds and IC chips to protect them from environmental factors such as moisture, mechanical stress, and thermal cycling.

– Cure the encapsulant material to harden it and ensure proper adhesion to the substrate and IC chips.

- Testing and Inspection:

– Perform electrical tests to verify the functionality and integrity of the wire bonds and IC chips.

– Conduct visual inspection to identify any defects such as wire shorts, open circuits, or voids in the encapsulant.

- Trim and Form (if necessary):

– Trim any excess wire lengths to ensure uniformity and optimize the overall package size.

– Form the leads or terminals of the substrate according to the desired configuration (e.g., flat leads, gull-wing leads) for surface mounting onto a printed circuit board (PCB).

- Packaging and Shipping:

– Package the wire bonding BGA substrates in protective materials or trays to prevent damage during shipping and handling.

– Label the packages with relevant information such as part number, date code, and manufacturing batch for traceability.

Throughout the manufacturing process, strict quality control measures should be implemented to ensure that the wire bonding BGA substrates meet the required specifications for reliability and performance in various semiconductor applications.

How much should Wire Bonding BGA Substrates cost?

The cost of wire bonding BGA (Ball Grid Array) substrates can vary depending on several factors, including the complexity of the substrate design, materials used, manufacturing processes involved, and quantity ordered. Here are some key factors that influence the cost:

- Substrate Material: The type of substrate material chosen can significantly impact the cost. Ceramic substrates are typically more expensive than FR-4 or laminate substrates due to their higher material and manufacturing costs.

- Design Complexity: Complex substrate designs with finer pitches, multiple layers, and special features will require more advanced manufacturing processes, which can increase the cost.

- Metallization Process: The method used for metallization, such as sputtering or electroplating, can affect the cost of the substrate fabrication.

- Wire Bonding: The cost of wire bonding includes equipment setup, wire material, labor, and testing. More complex wire bonding processes or higher wire counts can increase the overall cost.

- Encapsulation Material: The type and quality of encapsulant material used for protecting the wire bonds and IC chips can impact the cost.

- Volume: Larger quantities of wire bonding BGA substrates typically result in lower unit costs due to economies of scale. However, initial setup costs may be higher for small production runs.

- Supplier and Location:Different suppliers may offer varying prices for similar wire bonding BGA substrates. Additionally, manufacturing in regions with higher labor or material costs may result in higher overall costs.

- Additional Services: Additional services such as testing, inspection, trimming, forming, and packaging can add to the overall cost.

It’s essential for customers to work closely with substrate manufacturers or suppliers to understand the cost breakdown and factors affecting pricing for their specific requirements. Generally, prices for wire bonding BGA substrates can range from a few dollars to tens of dollars per unit, depending on the factors mentioned above.

What is Wire Bonding BGA Substrates base material?

The base material for wire bonding BGA (Ball Grid Array) substrates can vary depending on the specific requirements of the application. Some common base materials used in the fabrication of BGA substrates include:

- FR-4 (Flame Retardant 4): FR-4 is a widely used substrate material in electronics manufacturing due to its cost-effectiveness, good mechanical properties, and ease of processing. It is a fiberglass-reinforced epoxy laminate.

- Ceramics: Ceramics such as alumina (Al2O3) and aluminum nitride (AlN) are often used in high-performance applications where superior thermal conductivity, mechanical strength, and reliability are required. Ceramics are especially suitable for applications in harsh environments or high-temperature conditions.

- Laminates:Laminates are composed of multiple layers of materials such as fiberglass cloth impregnated with epoxy resin. They offer a balance of cost, mechanical properties, and electrical performance. Laminates can be customized with specific characteristics to meet the requirements of the application.

- Copper Substrates: Copper substrates provide excellent thermal conductivity and can be used in applications where heat dissipation is critical. Copper substrates are often used in power electronics and high-frequency applications.

- Metal-Core PCBs (MCPCBs): MCPCBs feature a metal core, typically aluminum or copper, sandwiched between layers of dielectric material. They offer superior thermal management capabilities and are commonly used in LED lighting, automotive, and power electronics applications.

The choice of base material depends on factors such as thermal management requirements, electrical performance, mechanical strength, cost considerations, and the specific needs of the application. Each material has its advantages and disadvantages, and selecting the appropriate material is crucial to ensure the reliability and performance of the wire bonding BGA substrates.

Which company makes Wire Bonding BGA Substrates?

Many companies offer manufacturing services for wire bonding BGA (Ball Grid Array) substrates, including large companies in the semiconductor packaging and assembly field, specialized electronic manufacturing service providers, as well as semiconductor materials and equipment suppliers. Some well-known companies include Amkor Technology, ASE Group, STATS ChipPAC, Unisem, ChipMOS Technologies, and others. These companies have extensive experience and expertise in manufacturing and providing various types of BGA substrates.

Our company is also one of the manufacturers of BGA substrates, specializing in providing high-quality, customized wire bonding BGA substrates. As a manufacturer, we have advanced manufacturing equipment and technology, as well as an experienced engineering team, capable of meeting the various needs and requirements of our customers. We are committed to providing customized solutions to our customers, offering BGA substrate design and manufacturing services tailored to their application specifications and requirements.

Our production processes and quality control systems ensure that the BGA substrates we produce have stable quality and reliable performance. We use high-quality substrate materials and employ advanced processing and testing techniques to ensure that each product meets our customers’ specifications. We also provide comprehensive after-sales service and technical support to ensure customer satisfaction and product performance.

By choosing our company as your supplier of BGA substrates, you can benefit from the following advantages:

- Customized solutions:Providing customized design and manufacturing services tailored to your specific requirements.

- High quality and reliability:We employ advanced production processes and strict quality control to ensure stable and reliable product quality and performance.

- Professional technical support:Our experienced engineering team can provide professional technical support and solutions.

- Competitive prices: We offer competitive prices and strive to provide the best value for our customers.

In summary, our company is a professional manufacturer of BGA substrates, offering high-quality, customized products, and professional technical support. We welcome you to cooperate with us for mutual development.

What are the 7 qualities of good customer service?

Good customer service is essential for building strong relationships with customers and fostering loyalty. Here are seven qualities that define good customer service:

- Responsiveness: A good customer service team is prompt in responding to customer inquiries, concerns, or requests. Whether it’s answering a phone call, replying to an email, or addressing a complaint on social media, being responsive shows that you value the customer’s time and are committed to helping them promptly.

- Empathy: Empathy involves understanding and relating to the customer’s emotions, concerns, and perspective. Empathetic customer service representatives listen actively, acknowledge the customer’s feelings, and demonstrate genuine care and concern. This helps build trust and rapport with customers, even in challenging situations.

- Knowledgeability: Good customer service requires having a deep understanding of the products or services offered, as well as the company’s policies, procedures, and systems. Knowledgeable representatives can provide accurate information, answer questions confidently, and offer helpful solutions to customers’ problems or inquiries.

- Professionalism: Professionalism encompasses aspects such as courtesy, politeness, and professionalism in communication and behavior. Customer service representatives should maintain a professional demeanor at all times, treating customers with respect and courtesy, regardless of the situation.

- Flexibility: Good customer service involves being adaptable and flexible to meet the diverse needs and preferences of customers. This may include offering multiple channels for communication (e.g., phone, email, live chat), accommodating special requests, or finding creative solutions to unique customer situations.

- Problem-solving skills: Effective problem-solving skills are crucial for resolving customer issues and complaints efficiently and satisfactorily. Customer service representatives should be proactive in identifying and addressing problems, seeking solutions, and following up to ensure customer satisfaction.

- Consistency: Consistency in customer service is key to building trust and loyalty. Customers expect a consistent experience across all interactions with a company, whether it’s online, over the phone, or in person. Consistency in service delivery, communication, and policies helps reinforce the company’s brand image and reputation.

By embodying these qualities, businesses can provide exceptional customer service experiences that delight customers, build loyalty, and drive long-term success.

FAQs

What is a wire bonding BGA substrate?

A wire bonding BGA substrate is a type of packaging technology used in semiconductor devices, particularly in Ball Grid Array (BGA) packages. It involves wire bonding to establish electrical connections between the integrated circuit chip and the substrate.

How does wire bonding work in BGA substrates?

Wire bonding involves using thin wires, typically made of gold or aluminum, to connect the electrical pads on the surface of the integrated circuit chip to the corresponding pads on the substrate. This process is typically done using heat, pressure, and ultrasonic energy to create a reliable electrical connection.

What are the advantages of wire bonding BGA substrates?

Wire bonding BGA substrates offer several advantages, including high-density interconnection, cost-effectiveness, reliability, and flexibility in design. They are suitable for a wide range of semiconductor applications where space constraints and high pin counts are important.

What are the key design considerations for wire bonding BGA substrates?

Design considerations include pad placement and size, pad pitch, pad metallization, wire loop height and length, substrate material and thickness, thermal management, and testing and inspection processes.

What materials are commonly used for wire bonding BGA substrates?

Common substrate materials include FR-4, ceramics, laminates, and metal-core PCBs (MCPCBs). The choice of material depends on factors such as thermal management requirements, mechanical strength, and cost considerations.

What are the steps involved in manufacturing wire bonding BGA substrates?

The manufacturing process typically involves substrate preparation, metallization, die attach, wire bonding, encapsulation, testing and inspection, trim and form (if necessary), and packaging and shipping.

How much do wire bonding BGA substrates cost?

The cost of wire bonding BGA substrates varies depending on factors such as substrate material, design complexity, volume, supplier, and additional services required. Prices can range from a few dollars to tens of dollars per unit.

Which companies manufacture wire bonding BGA substrates?

Several companies specialize in the manufacturing of wire bonding BGA substrates, including Amkor Technology, ASE Group, STATS ChipPAC, Unisem, and ChipMOS Technologies, among others.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer