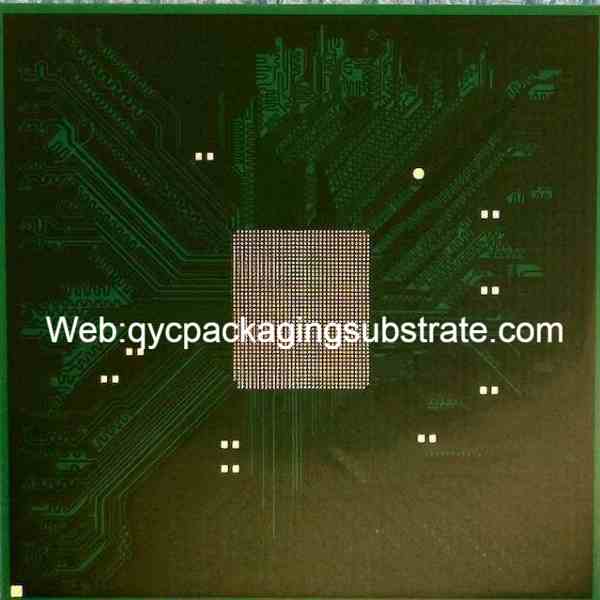

Organic Package Substrate Manufacturer. Advanced Msap and Sap technology, High multilayer interconnection substrates from 4 to 20 layer. High speed and high frequency substrates.

In the ever-evolving realm of electronic engineering, the selection of package substrates stands as a decisive factor influencing the comprehensive performance and dependability of electronic devices. As technological progress propels forward, there is a mounting need for substrates that not only satisfy stringent electrical and thermal criteria but also resonate with the escalating call for sustainability and eco-friendly practices. This introduction aims to offer a succinct glimpse into the world of package substrates, underscore the paramount significance of choosing the appropriate substrate in electronic engineering, and illuminate the increasing significance of organic package substrates.

Brief Overview of Package Substrates

Package substrates play a crucial role as the foundational bedrock for electronic components, enabling the seamless interconnection of diverse elements within a device. Historically, substrates were primarily crafted from materials such as ceramics and fiberglass. Nevertheless, as electronic devices undergo rapid evolution, there is a compelling need to transition towards more sophisticated and advanced materials.

Importance of Choosing the Right Substrate in Electronic Engineering

The success of electronic engineering endeavors hinges on the meticulous selection of suitable substrates. An ill-fitted substrate can lead to compromised electrical performance, increased thermal issues, and a shorter lifespan for the electronic device. Therefore, understanding the nuances of different substrates and their impact on device functionality is crucial for engineers and designers alike.

Focus on the Emergence and Significance of Organic Package Substrates

Amidst the myriad choices available, organic package substrates have emerged as a cutting-edge solution with multifaceted advantages. These substrates, often derived from organic materials like polymers, not only exhibit superior electrical performance but also address environmental concerns.Amidst the electronics industry’s increasing emphasis on sustainability, the importance of organic substrates is burgeoning, propelling them into the spotlight of exploration and innovation. In the following segments, we will intricately examine organic package substrates, unveiling their distinctive attributes and highlighting their role as a guiding light in the ever-evolving landscape of electronic engineering.

Understanding Organic Package Substrates

Definition and Composition of Organic Package Substrates

Definition: Organic package substrates refer to the base material in electronic packaging that is composed primarily of organic compounds. These compounds often include polymers and resins, providing a flexible and versatile foundation for electronic components.

Composition: The organic substrates are typically constructed using materials like epoxy resins, polyimides, or BT (Bismaleimide Triazine) resins. These materials contribute to the substrate’s ability to offer a balance between flexibility and durability, crucial in various electronic applications.

How Organic Substrates Differ from Traditional Materials

Flexibility and Form Factor Redefined: In contrast to conventional materials like ceramics or metals, organic substrates introduce a heightened level of flexibility. This characteristic empowers the design and manufacture of electronic devices that are not only thinner but also significantly lighter, meeting the contemporary imperative for miniaturization in the electronics industry.

Cost-Effectiveness: Organic substrates often present a more cost-effective solution compared to traditional materials. The production processes for organic substrates are generally more efficient, contributing to a reduction in manufacturing costs.

Dielectric Properties: Organic materials tend to have better dielectric properties than some traditional alternatives. This contributes to improved insulation and reduced signal interference, enhancing the overall performance of electronic components.

Key Features That Make Organic Substrates a Preferred Choice

High Signal Integrity: The dielectric properties of organic substrates result in minimal signal loss during transmission. Ensuring robust signal integrity holds paramount importance in the dependable functioning of electronic devices, particularly in scenarios demanding high-frequency applications.

Streamlined Manufacturing: Organic substrates offer a manufacturing advantage through cost-effective and scalable processes, positioning them as an ideal choice for mass production. This streamlined manufacturing approach not only reduces production costs but also significantly shortens production cycles, enabling faster time-to-market for electronic products.

Compatibility with Advanced Technologies:The versatility of organic substrates positions them as a fitting choice for seamless integration with cutting-edge technologies like 5G, IoT, and high-performance computing.Their properties align with the demands of cutting-edge electronic applications.

Reduced Environmental Impact: Organic substrates often have a lower environmental impact compared to traditional materials. The use of eco-friendly materials and efficient manufacturing processes contributes to sustainability goals in electronic engineering.

Customization Possibilities: The flexibility of organic substrates allows for easy customization of shapes and sizes, accommodating the diverse design requirements of modern electronic devices.

Understanding the composition, differences, and key features of organic package substrates is fundamental in appreciating their role in advancing electronic engineering and meeting the evolving demands of the industry.

Advantages of Organic Package Substrates

Enhanced Electrical Performance

1.Improved Signal Integrity

Reduced signal distortion: Organic substrates exhibit lower dielectric loss, ensuring signals maintain their integrity over longer distances.

Minimal cross-talk: Enhanced isolation properties contribute to a significant reduction in electromagnetic interference between traces.

2.Lower Electrical Losses

Inherent dielectric properties: Organic materials possess lower intrinsic electrical losses, leading to more efficient power delivery.

Reduced resistance: The substrate’s composition allows for better conductivity, minimizing resistive losses in the transmission of electrical signals.

Thermal Efficiency

1.Higher Thermal Conductivity

Efficient heat transfer: Organic substrates facilitate improved thermal conduction, effectively transferring heat away from sensitive electronic components.

Enhanced reliability: Lower thermal resistance ensures stable operating temperatures, preventing overheating issues.

2.Efficient Heat Dissipation

Advanced cooling capabilities: The organic composition promotes effective dissipation of heat generated during device operation.

Heat management in high-density components: Organic substrates excel in managing thermal challenges associated with densely packed electronic assemblies.

Environmental Impact

1.Sustainability and Eco-friendliness

Biodegradable materials: Organic substrates often incorporate environmentally friendly, biodegradable components, aligning with sustainable manufacturing practices.

Reduced reliance on non-renewable resources: Organic materials offer an alternative to traditional substrates derived from less sustainable sources.

2.Reduced Environmental Footprint Compared to Alternatives

Energy-efficient production: The manufacturing process of organic substrates typically requires less energy compared to conventional alternatives, contributing to a lower carbon footprint.

Recycling viability: Organic substrates are often more easily recyclable, reducing electronic waste and promoting a circular economy.

This expanded section delves deeper into the specific advantages of organic package substrates, providing a more comprehensive understanding of their electrical, thermal, and environmental benefits.

Applications of Organic Package Substrates

Consumer Electronics

1.Mobile Devices

Enhanced Signal Transmission: Organic package substrates, with their low dielectric constant, contribute to improved signal transmission in mobile devices, ensuring faster data transfer and reduced interference.

Lightweight Design: The mechanical flexibility of organic substrates allows for lighter and more compact mobile devices, meeting the demand for portable and sleek designs.

Cost-Effective Manufacturing: The cost efficiency of organic substrates makes them an attractive choice for mass-produced mobile devices, aligning with the consumer electronics market’s demand for affordability.

2.Wearable Technology

Flexible Form Factors: The mechanical flexibility of organic substrates enables the development of wearable devices with bendable and conformable designs, enhancing user comfort and wearability.

Compatibility with Biometric Sensors: Organic substrates prove ideal for integrating biometric sensors in wearable technology, ensuring accurate data capture in a lightweight and unobtrusive form.

Sustainability in Wearables: The environmental friendliness of organic materials aligns with the growing emphasis on sustainable practices in the production of wearable technology.

Automotive Industry

1.In-Vehicle Electronics

Space Optimization: Organic substrates contribute to compact and space-efficient in-vehicle electronic systems, addressing the limited space within modern automobiles.

Temperature Stability: Leveraging the robust thermal properties inherent in organic substrates, these materials prove exceptionally well-suited for in-vehicle applications. Their capacity to maintain stable performance spans a broad temperature spectrum, ensuring reliability and functionality even in diverse and challenging automotive environments.

Integration with Infotainment Systems: The inherent compatibility of organic substrates with advanced technologies positions them as ideal components for seamless integration into in-vehicle infotainment systems. This integration not only augments the overall driving experience but also underscores the adaptability of organic substrates in meeting the demands of modern automotive technology.

2.Advanced Driver-Assistance Systems (ADAS)

High-Frequency Capabilities: Organic substrates support the high-frequency requirements of ADAS components, contributing to the development of responsive and accurate driver-assistance systems.

Reliability in Harsh Conditions: The robust nature of organic substrates makes them resilient to the challenging conditions encountered in automotive environments, ensuring the reliability of ADAS functionalities.

Cost-Effective Solutions for Mass Adoption: The cost efficiency of organic substrates aligns with the automotive industry’s need for affordable and scalable solutions, fostering the widespread adoption of ADAS technologies.

Aerospace and Defense

1.Spacecraft Electronics

Weight Reduction in Spacecraft Design: The lightweight nature of organic substrates contributes to overall weight reduction in spacecraft, a critical factor in space exploration missions.

Radiation Resistance: Organic substrates exhibit resistance to radiation, enhancing their suitability for use in the harsh space environment and ensuring the reliability of spacecraft electronics.

Integration with Communication Systems: Compatibility with high-frequency applications makes organic substrates well-suited for spacecraft communication systems, facilitating reliable data transmission.

2.Military Applications

Durability in Extreme Conditions: Organic substrates’ mechanical flexibility and durability make them suitable for military applications, where equipment may be subjected to extreme conditions.

Secure Signal Transmission: Enhanced signal integrity contributes to secure data transmission in military electronics, aligning with the stringent requirements of defense applications.

Cost-Efficient Manufacturing for Defense Systems: The cost efficiency of organic substrates provides a practical solution for manufacturing electronic components used in military equipment, meeting budget constraints without compromising performance.

Conclusion

Recap of the Key Advantages of Organic Package Substrates

In the dynamic landscape of electronic engineering, organic package substrates emerge as a transformative solution, offering a host of advantages that redefine industry standards. These substrates, composed of eco-friendly and flexible materials, present a paradigm shift in electronic packaging. Key advantages include:

Enhanced Electrical Performance: With a remarkably low dielectric constant, organic package substrates facilitate improved signal integrity, minimizing signal distortion and crosstalk.

Mechanical Flexibility: The lightweight and flexible nature of organic substrates make them ideal for applications with spatial constraints or dynamic environments, providing engineers with unprecedented design flexibility.

Cost Efficiency: Organic substrates not only contribute to enhanced performance but also boast lower manufacturing costs, aligning with the demand for scalable and cost-effective solutions in the competitive electronics industry.

Environmental Friendliness: In an era where sustainability is paramount, organic package substrates stand out as a biodegradable and recyclable alternative, fostering a greener approach to electronic engineering.

Compatibility with Advanced Technologies: Organic substrates seamlessly integrate with cutting-edge technologies such as 5G and IoT, positioning them at the forefront of innovation in electronic packaging.

Call to Action for Engineers and Manufacturers to Explore this Innovative Solution

As we stand at the intersection of technology and sustainability, the adoption of organic package substrates becomes a strategic imperative for forward-thinking engineers and manufacturers. Now is the opportune moment to delve into the integration of these substrates into your designs, heralding a transformative era in electronic engineering. Here’s your decisive call to action:

Research and Development Collaboration: Foster collaborations between research and development teams to delve deeper into the unique properties and applications of organic package substrates.

Training and Skill Development: Equip your engineering teams with the knowledge and skills necessary to leverage the full potential of organic substrates, ensuring a seamless transition into this innovative technology.

Supply Chain Integration: Work closely with suppliers to integrate organic substrates into your supply chain, optimizing production processes and realizing the cost efficiencies associated with these materials.

Industry Networking and Collaboration: Engage with industry peers and associations to share insights, experiences, and best practices related to the adoption of organic substrates, contributing to the collective growth of the electronic engineering community.

By embracing organic package substrates, engineers and manufacturers have the opportunity to not only elevate the performance of electronic devices but also contribute to a more sustainable and resilient future. The journey towards innovation begins with exploration, and organic substrates pave the way for a transformative electronic engineering landscape.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer