Cavities Substrate

Cavities Substrate Vendor, Open a cavity on the PCBs, the Cavity PCBs can be produced from a variety of materials, High TG FR4, BT , High frequency and high speed materials,ceramic, metal materials, We specialize in the production of Cavity PCBs from 4L to 30 layers. Cavity substrates are specialized material structures used in the construction of microelectronic devices, particularly in high-frequency and microwave applications. These substrates provide a platform for integrating active and passive components while offering controlled electromagnetic properties. Typically made from materials such as ceramics, semiconductors, or polymers, cavity substrates feature a cavity or void within their structure. This cavity serves multiple purposes, including housing components, creating resonant cavities for specific electromagnetic effects, and facilitating thermal management. The fabrication process of cavity substrates involves various techniques such as etching, drilling, and deposition to create the desired structure. With their ability to improve electrical performance, enhance thermal management, and reduce signal interference, cavity substrates find applications in telecommunications, radar systems, satellite communications, aerospace electronics, and medical devices. Quality considerations such as material purity, dimensional accuracy, and reliability are paramount in ensuring the optimal performance of cavity substrates in diverse electronic applications.

What is a Cavity Substrate?

Cavity Substrate| Package substrate manufacturing. the Package Substrate will be made with Showa Denko and Ajinomoto High speed materials.or other types high speed materials and high frequency materials.

A cavity substrate typically refers to a specialized material structure used in the construction of microelectronic devices such as microwave integrated circuits (MICs), microwave monolithic integrated circuits (MMICs), and radio frequency (RF) devices. The cavity substrate provides a platform for the integration of active and passive components such as transistors, capacitors, and resistors, while also offering a controlled electromagnetic environment for optimal device performance.

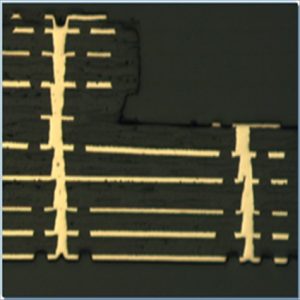

The cavity substrate is often designed to have a cavity or void within its structure, which can be used for housing components or creating resonant cavities for specific electromagnetic effects. This cavity may be created using various techniques such as etching, drilling, or milling within the substrate material.

The choice of substrate material for cavity substrates is crucial, as it directly impacts the electrical, thermal, and mechanical properties of the device. Common substrate materials include ceramics, semiconductors, and certain types of polymers, each offering different advantages and limitations in terms of performance, cost, and manufacturability.

Overall, cavity substrates play a vital role in the development of high-frequency and microwave devices, enabling compact, high-performance solutions for applications ranging from telecommunications and radar systems to satellite communications and aerospace electronics.

Cavities Substrate

What are the Cavity Substrate Design Guidelines?

Here are some common design guidelines for cavity substrates:

- Electrical Performance:Select materials and design structures to achieve the desired electrical characteristics, such as dielectric constant, loss tangent, thermal conductivity, etc.

- Size and Shape:Determine the size, shape, and layout of the cavity to meet the device’s size constraints and electromagnetic performance requirements.

- Coupling and Isolation:Optimize coupling and isolation between the cavity and components to prevent unnecessary signal interference and crosstalk.

- Thermal Management:Design appropriate heat conduction paths and heat dissipation structures to ensure stable temperatures during operation.

- Mechanical Stability:Consider the mechanical strength and stability of the cavity substrate to meet environmental stress and vibration requirements.

- Manufacturability:Ensure the design is feasible and easy to manufacture, considering production costs, process feasibility, and manufacturing constraints.

- High-Frequency Performance:Minimize RF signal losses and distortions while maintaining signal stability and accuracy.

- Electromagnetic Compatibility (EMC):Address EMC issues to ensure compliance with relevant EMC standards and reliable operation in complex electromagnetic environments.

These guidelines are typically key factors to consider when designing cavity substrates, ensuring that the final device meets the specific requirements of its application and delivers excellent performance.

What is the Cavity Substrate Fabrication Process?

The fabrication process of cavity substrates involves several steps to create the desired structure for housing components and providing the necessary electromagnetic environment. Here is a general overview of the typical cavity substrate fabrication process:

- Substrate Selection:Choose a suitable substrate material based on the desired electrical, thermal, and mechanical properties. Common substrate materials include ceramics, semiconductors, and certain types of polymers.

- Design/Layout:Design the layout of the cavity substrate, including the placement of components, the shape and size of the cavity, and the routing of interconnects. This step often involves CAD software to create detailed design plans.

- Substrate Preparation:Prepare the substrate surface by cleaning and possibly roughening it to improve adhesion of subsequent layers or materials.

- Cavity Formation:Create the cavity within the substrate material using techniques such as etching, drilling, milling, or laser ablation. The cavity is typically designed to accommodate specific components or to create resonant cavities for electromagnetic effects.

- Layer Deposition:Deposit additional layers of materials onto the substrate surface as needed. This may include metal layers for interconnects, dielectric layers for insulation, or semiconductor layers for active components.

- Component Integration:Integrate active and passive components onto the substrate surface within or around the cavity. This may involve processes such as soldering, wire bonding, or flip-chip bonding.

- Interconnect Formation:Create electrical connections between components and substrate layers using techniques such as wire bonding, flip-chip bonding, or conductive adhesive bonding.

- Encapsulation/Sealing:Encapsulate the components and substrate layers with a protective layer or sealant to protect against environmental factors such as moisture, dust, and mechanical damage.

- Testing and Quality Control:Perform testing and quality control measures to ensure that the fabricated cavity substrate meets the desired specifications and performance requirements.

- Packaging:Package the fabricated cavity substrate into the final form factor suitable for integration into larger electronic systems or devices.

Throughout the fabrication process, careful attention is paid to maintaining dimensional accuracy, material properties, and cleanliness to ensure the optimal performance and reliability of the final cavity substrate.

How do you manufacture a Cavity Substrate?

The manufacturing process of a cavity substrate involves several steps to create the structure necessary for housing electronic components and providing the desired electromagnetic properties. Here’s a general outline of the manufacturing process:

- Substrate Preparation:The process begins with selecting a suitable substrate material, such as ceramics, semiconductors, or certain polymers, based on the required electrical, thermal, and mechanical properties. The substrate surface is cleaned and prepared for subsequent processing steps.

- Design/Layout:The layout of the cavity substrate is designed using computer-aided design (CAD) software. This includes determining the placement of components, the size and shape of the cavity, and the routing of interconnects.

- Cavity Formation:The cavity is created within the substrate material using various techniques such as etching, drilling, milling, or laser ablation. The cavity may be designed to accommodate specific components or to create resonant cavities for electromagnetic effects.

- Layer Deposition:Additional layers of materials are deposited onto the substrate surface as needed. This may involve processes such as physical vapor deposition (PVD), chemical vapor deposition (CVD), spin coating, or screen printing. These layers may include metal layers for interconnects, dielectric layers for insulation, or semiconductor layers for active components.

- Component Integration:Active and passive components are integrated onto the substrate surface within or around the cavity. This may involve processes such as soldering, wire bonding, or flip-chip bonding. Components are carefully placed and aligned according to the design layout.

- Interconnect Formation:Electrical connections between components and substrate layers are established using techniques such as wire bonding, flip-chip bonding, or conductive adhesive bonding. These connections ensure proper electrical conductivity and signal transmission between components.

- Encapsulation/Sealing:The components and substrate layers are encapsulated with a protective layer or sealant to safeguard against environmental factors such as moisture, dust, and mechanical damage. This may involve processes such as conformal coating, potting, or encapsulation molding.

- Testing and Quality Control:The fabricated cavity substrate undergoes rigorous testing and quality control measures to ensure that it meets the required specifications and performance criteria. This includes electrical testing, visual inspection, and dimensional measurements.

- Packaging:Once testing and quality control are completed, the cavity substrate is packaged into its final form factor suitable for integration into larger electronic systems or devices. This may involve mounting the substrate onto a carrier or placing it within a protective housing.

Throughout the manufacturing process, strict adherence to quality standards, precision machining techniques, and thorough quality control measures are essential to produce cavity substrates with optimal performance and reliability.

How much should a Cavity Substrate cost?

The cost of a cavity substrate can vary widely depending on several factors such as the substrate material, fabrication techniques, complexity of design, size, quantity, and required tolerances. Here are some key considerations that can influence the cost:

- Substrate Material:Different materials have varying costs. For example, ceramic substrates tend to be more expensive than certain polymers or metals.

- Fabrication Techniques:The manufacturing processes involved, such as etching, drilling, milling, or laser ablation, can affect the overall cost. More complex or specialized techniques may incur higher costs

- Design Complexity:The complexity of the cavity substrate design, including the number of layers, components, and the intricacy of the layout, can impact the cost of fabrication.

- Size and Quantity:Larger substrates and higher quantities typically result in higher production costs due to material usage, processing time, and economies of scale.

- Tolerances and Specifications: Tighter tolerances and specific performance requirements may necessitate additional manufacturing steps or quality control measures, which can increase the cost.

- Additional Processes:Any additional processes such as surface finishing, coating, or testing may contribute to the overall cost.

It’s challenging to provide a specific cost estimate without knowing the exact specifications and requirements of the cavity substrate. Costs can range from a few dollars for simple substrates to hundreds or even thousands of dollars for more complex, specialized designs. Additionally, factors such as market conditions, supplier pricing, and project timelines can also influence the overall cost.

If you’re considering the fabrication of a cavity substrate, it’s best to consult with manufacturers or suppliers who specialize in microelectronics or substrate fabrication. They can provide more accurate cost estimates based on your specific needs and requirements.

What is Cavity Substrate base material?

The base material for a cavity substrate can vary depending on the specific application requirements and desired characteristics of the substrate. Some common materials used as the base material for cavity substrates include:

- Ceramics:Ceramic materials such as alumina (Al2O3), aluminum nitride (AlN), and beryllium oxide (BeO) are widely used for cavity substrates due to their excellent electrical insulation properties, high thermal conductivity, and mechanical strength.

- Semiconductors: Semiconductor materials such as silicon (Si) are also used for cavity substrates, especially in applications where integration with semiconductor devices or compatibility with semiconductor fabrication processes is necessary.

- Polymers:Certain polymers and polymer composites can be used as base materials for cavity substrates, offering advantages such as flexibility, low cost, and ease of processing. Examples include liquid crystal polymer (LCP) and polytetrafluoroethylene (PTFE).

- Metals:Metals such as copper (Cu) or aluminum (Al) can be used as base materials for cavity substrates, especially in applications where high thermal conductivity and excellent electrical conductivity are required. However, metal substrates may require additional surface treatments or insulation layers to prevent interference with electronic components.

- Glass:Glass substrates are used in some specialized applications, offering advantages such as high optical transparency, chemical inertness, and compatibility with certain fabrication processes.

The choice of base material depends on factors such as electrical properties, thermal conductivity, mechanical strength, compatibility with manufacturing processes, cost considerations, and environmental factors. It’s important to select a base material that best meets the specific requirements of the cavity substrate design and intended application.

Which company makes Cavity Substrates?

Many companies manufacture cavity substrates, including major companies such as Murata Manufacturing Co., KYOCERA Corporation, and Rogers Corporation. These companies have extensive experience and technological expertise in the microwave and RF fields, and they can provide various types and specifications of cavity substrates to meet the needs of different applications.

As for our company, we are also a professional manufacturer specializing in microwave and RF device production. We have advanced production equipment and a skilled technical team capable of designing and manufacturing high-quality cavity substrates to meet customers’ specific requirements and specifications.

Our company has the following advantages in producing high-quality cavity substrates:

- Professional Team:We have experienced engineers and technicians with deep expertise in microwave and RF device design and manufacturing. They can provide customers with professional technical support and customized solutions.

- Advanced Equipment:We possess advanced production equipment and process technologies, including precision machining equipment, advanced material processing techniques, and strict quality control systems to ensure that the produced cavity substrates have excellent performance and stability.

- Diverse Material Selection:We can use various materials to manufacture cavity substrates, including ceramics, semiconductors, metals, and polymers, to meet the requirements of different applications.

- Flexible Production Capacity:Our production capacity is flexible, allowing us to provide small-batch custom production or large-scale mass production according to customer needs, ensuring timely delivery and meeting customer requirements.

- Quality Assurance:We strictly adhere to ISO quality management systems to ensure that the produced cavity substrates comply with international standards and customer quality requirements, guaranteeing stable and reliable product quality.

In summary, our company has extensive experience, advanced equipment, and a professional team capable of providing high-quality customized cavity substrates to meet various customer needs and requirements.

What are the 7 qualities of good customer service?

Good customer service is essential for maintaining customer satisfaction and loyalty. Here are seven qualities that contribute to excellent customer service:

- Responsiveness:Good customer service involves promptly addressing customer inquiries, concerns, and requests. Being responsive shows customers that their needs are valued and that the company is committed to providing assistance in a timely manner.

- Empathy:Empathy involves understanding and acknowledging the customer’s feelings, concerns, and perspectives. Demonstrating empathy helps build rapport with customers and fosters a positive relationship by showing that the company cares about their experiences and is willing to help resolve any issues they may have.

- Clear Communication:Effective communication is crucial for providing good customer service. Customer service representatives should communicate clearly and concisely, using language that is easy to understand. They should also listen actively to customers, asking clarifying questions to ensure they fully understand the customer’s needs and concerns.

- Knowledgeability:Customers expect customer service representatives to be knowledgeable about the company’s products, services, policies, and procedures. Having a thorough understanding of the company’s offerings allows representatives to provide accurate information and assistance to customers, helping to build trust and credibility.

- Professionalism:Professionalism involves maintaining a positive and respectful attitude when interacting with customers, even in challenging situations. Customer service representatives should remain calm, courteous, and professional at all times, regardless of the customer’s behavior or the complexity of the issue.

- Flexibility:Good customer service requires flexibility and adaptability to meet the diverse needs and preferences of customers. This may involve offering personalized solutions, accommodating special requests, or being willing to escalate issues to higher levels of management when necessary.

- Follow-Up:Following up with customers after resolving their inquiries or issues shows that the company values their feedback and is committed to ensuring their satisfaction. Following up also provides an opportunity to gather additional feedback, address any lingering concerns, and further strengthen the relationship with the customer.

By embodying these qualities, businesses can deliver exceptional customer service that exceeds customer expectations and fosters long-term loyalty and advocacy.

FAQs (Frequently Asked Questions)

What is a cavity substrate?

A cavity substrate is a specialized material structure used in the construction of microelectronic devices, such as microwave integrated circuits (MICs) and radio frequency (RF) devices. It provides a platform for integrating active and passive components while offering controlled electromagnetic properties.

What materials are used for cavity substrates?

Common materials used for cavity substrates include ceramics, semiconductors, polymers, and metals. The choice of material depends on factors such as electrical properties, thermal conductivity, and mechanical strength.

What are the advantages of using cavity substrates?

Cavity substrates offer advantages such as improved electrical performance, enhanced thermal management, reduced signal interference, and increased reliability. They also enable the integration of components in a compact and efficient manner.

How are cavity substrates fabricated?

The fabrication process of cavity substrates involves steps such as substrate preparation, cavity formation, layer deposition, component integration, interconnect formation, encapsulation, testing, and packaging. Various techniques such as etching, drilling, and deposition are used during fabrication.

What are the applications of cavity substrates?

Cavity substrates are used in various applications, including telecommunications, radar systems, satellite communications, aerospace electronics, and medical devices. They are particularly well-suited for high-frequency and microwave applications.

What factors should be considered when designing cavity substrates?

Important factors to consider when designing cavity substrates include electrical performance, size and shape, coupling and isolation, thermal management, mechanical stability, manufacturability, high-frequency performance, and electromagnetic compatibility (EMC).

Where can cavity substrates be sourced?

Cavity substrates can be sourced from specialized manufacturers, suppliers, or distributors that specialize in microelectronics, RF components, or substrate fabrication. It’s essential to choose a reputable supplier with expertise in producing high-quality cavity substrates.

What are some quality considerations for cavity substrates?

Quality considerations for cavity substrates include material purity, dimensional accuracy, surface finish, electrical properties, thermal conductivity, and reliability. It’s important to ensure that cavity substrates meet the required specifications and performance standards for the intended application.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer