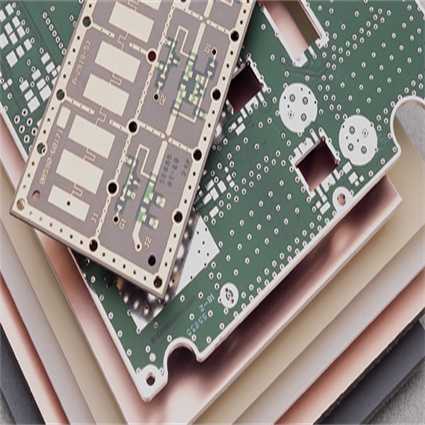

What is RT/duroid 5880 PCB?

RT/duroid 5880 PCB manufacturing. RT/duroid 5880 laminates has a low dielectric constant (Dk) and low dielectric loss, making them well suited for high frequency/broadband applications. Helping to maintain the Dk uniformity are the randomly oriented microfibers reinforcing the PTFE composites.

Features

- Dk or 2.20 +/- .02

- Dissipation factor of .0009 at 10GHz

- Low moisture absorption

- Isotropic

Benefits

- Uniform electrical properties over wide frequency range

- Easily cut, shared and machined to shape

- Resistant to solvents and reagents used in etching or plating edges and holes

- Ideal for high moisture environments

- Well-established material

- Lowest electrical loss for reinforced PTFE material

RT/duroid 5880 stands as a high-frequency laminate material employed in the assembly of printed circuit boards (PCBs). Manufactured by Rogers Corporation, a preeminent supplier of cutting-edge materials spanning diverse industries, this material is purpose-built for high-frequency applications, particularly in the realms of radio frequency (RF) and microwave circuits.

RT/duroid 5880 PCBs are meticulously designed to showcase stellar electrical properties, addressing scenarios where imperatives include low loss, high dielectric constant, and unwavering electrical performance.

The standout characteristics of RT/duroid 5880 encompass negligible dielectric loss, marginal moisture absorption, and steadfast electrical attributes covering an expansive frequency spectrum. These attributes position it favorably for integration into communication systems, radar setups, and various other high-frequency electronic devices.

PCBs fashioned with RT/duroid 5880 find themselves at home in environments where signal integrity takes precedence, with the material earning acclaim for its ability to consistently deliver reliable performance in high-frequency settings. It’s crucial to acknowledge that specific properties and applications may exhibit variations, underscoring the importance of referring to the manufacturer’s documentation for nuanced specifications.

How Does RT/duroid 5880 PCB Function?

The RT/duroid 5880 PCB operates at the forefront of high-frequency technology, intricately designed to excel in the intricate dance of radio frequency (RF) and microwave circuits. Let’s unravel the mechanics that drive the functionality of the RT/duroid 5880 PCB:

Material Alchemy: At its core lies a concoction of high-frequency laminate material, typically woven glass fortified with polytetrafluoroethylene (PTFE). This fusion gives birth to a substrate with bespoke electrical properties finely tuned to the cadence of high-frequency signals.

Dancing with Loss: A star performer in the ensemble is its ability to gracefully navigate minimal dielectric loss. This prowess is pivotal, orchestrating a symphony where energy dissipation takes a back seat during the transmission of signals. The result? Pristine signal integrity, a non-negotiable demand in the realm of high frequencies.

Elevation in Constants: The material’s high dielectric constant takes the spotlight, a virtuoso act in applications craving augmented capacitance. This property choreographs superior impedance matching and the seamless propagation of signals through the intricate steps of high-frequency circuits.

Consistent Electrical Ballet: Across a sweeping frequency range, the RT/duroid 5880 gracefully pirouettes with stable electrical characteristics. This reliability on the stage is the linchpin, ensuring a performance that remains unwavering and consistent in the face of diverse high-frequency challenges.

Versatility in Applause: From communication systems to radar setups, the RT/duroid 5880 PCB takes a bow in a variety of electronic devices waltzing through the high-frequency spectrum. Its inherent properties make it the prima ballerina in environments where the precision and reliability of signal transmission take the center stage.

Integrity Waltz: Through a meticulously choreographed design and the artistry of material properties, the RT/duroid 5880 PCB engages in an elegant waltz to preserve signal integrity. This involves minimizing losses, reflections, and distortions—a dance that holds a special place in the grand performance of wireless communication.

In summary, the RT/duroid 5880 PCB doesn’t just function; it dances through the intricacies of high-frequency realms, with its material composition and design orchestrating a symphony that celebrates minimal losses, elevated constants, and a consistent electrical ballet. It is the lead performer in the grand production of high-frequency electronic circuits, where signal integrity is the star of the show.

What are the Different Types of RT/duroid 5880 PCB?

Explore the diverse landscape of RT/duroid 5880 PCBs, each tailored to meet unique application demands. Here’s a glimpse into the different types:

Single-Layer Serenity: Embark on simplicity with single-layer RT/duroid 5880 PCBs. Perfect for straightforward applications where circuit complexity takes a back seat.

Double-Layer Dynamics: Elevate the game with double-layer RT/duroid 5880 PCBs. Two layers of substrate provide flexibility in trace routing, ideal for circuits with a touch of complexity.

Multilayer Mastery: The symphony of three or more substrate layers intertwined with copper heralds the era of multilayer RT/duroid 5880 PCBs. Navigate the realm of high density and intricate circuits with improved signal integrity.

Flexibility Unleashed: Unveil the flexibility of RT/duroid 5880 with Flex PCBs. Designed to bend and mold to specific shapes, these boards shine in applications with space constraints or a demand for flexibility.

Rigid-Flex Fusion: Marrying the best of both worlds, Rigid-Flex RT/duroid 5880 PCBs seamlessly blend rigidity and flexibility. A harmonious choice for applications craving a perfect balance.

High-Frequency Marvels: Tailored for the fast-paced world of high frequencies, these RT/duroid 5880 PCBs optimize features to minimize signal loss, ensuring top-notch performance in RF and microwave circuits.

Antenna Artistry: Crafted for communication and signal reception, RT/duroid 5880 finds its place in the creation of PCBs for antennas. Elevate your connectivity game with high-frequency precision.

Power Amplifier Prowess: When power amplification takes the spotlight, specialized RT/duroid 5880 PCBs step up to the challenge. Designed to handle power requirements while maintaining peak high-frequency performance.

In the intricate dance of electronic circuits, the choice of RT/duroid 5880 PCB type is a tailored performance, dictated by the frequency range, signal integrity needs, flexibility requirements, and the overall complexity of the application. Manufacturers stand ready to craft custom configurations, ensuring a perfect match for specific project demands.

How Does RT/duroid 5880 PCB Relate to IC Package Technology?

The dynamic interplay between RT/duroid 5880 PCB and integrated circuit (IC) package technology unfolds as a nuanced partnership, especially in the realm of high-frequency circuits. Let’s delve into the intricate facets of this collaboration:

High-Frequency Choreography: RT/duroid 5880 PCB takes the lead in orchestrating the dance of high-frequency signals. With its remarkable electrical properties, characterized by minimal dielectric loss and a high dielectric constant, the PCB becomes a conductor, guiding the symphony of high-frequency transmissions alongside ICs designed for this dynamic range.

Impedance Ballet: In the delicate ballet of high-frequency circuits, achieving precise impedance matching is akin to a well-choreographed dance. RT/duroid 5880 PCBs gracefully waltz into this scenario, offering a platform for controlled impedance that harmonizes seamlessly with the impedance characteristics of ICs. This ensures an elegant dance of efficient signal transfer.

Miniaturization Waltz: As ICs elegantly waltz towards miniaturization, RT/duroid 5880 PCBs join the dance. Their flexible design allows for intricate layouts and routing, creating an enchanting stage for compact arrangements that accommodate the evolving landscape of densely packed ICs.

Thermal Pas de Deux: Temperature management becomes a graceful pas de deux in the performance of ICs, particularly in high-frequency applications. RT/duroid 5880 PCBs gracefully join this dance, facilitating an efficient thermal exchange. This contribution adds to the overall ballet of thermal management in IC packages.

RF and Microwave Performance Symphony: RT/duroid 5880 PCBs take center stage in the symphony of RF and microwave applications. The material’s finely tuned properties resonate with the demands of these applications, enriching the overall performance and reliability of the electronic system.

Custom Couture for IC Elegance: RT/duroid 5880 PCBs emerge as the skilled couturiers of the electronic realm, offering bespoke tailoring to suit the unique needs of different ICs. The material’s properties can be artfully customized, ensuring a tailored fit for optimal performance across diverse applications.

In essence, the partnership between RT/duroid 5880 PCB and IC package technology is a dance of precision and artistry. Together, they compose a symphony that elevates signal integrity, synchronizes impedance, embraces miniaturization, manages thermal dynamics, and caters to the unique demands of high-frequency ICs. This collaborative performance resonates in applications ranging from communication systems to radar setups, where the frequency beat takes center stage.

What Sets RT/duroid 5880 PCB Apart from Traditional PCBs?

RT/duroid 5880 PCB emerges as a standout performer in the realm of high-frequency applications, distinguishing itself from traditional PCBs through a host of unique characteristics:

Elevated Frequency Prowess: Engineered for excellence in high-frequency scenarios, RT/duroid 5880 PCB takes the stage in RF and microwave circuits, where its material properties shine.

Efficiency in Energy Transmission: One of its defining features is the low dielectric loss. This quality translates into efficient signal transmission, minimizing energy dissipation as heat. In applications where signal accuracy is non-negotiable, this sets RT/duroid 5880 apart.

Dielectric Eminence: Boasting a high dielectric constant, RT/duroid 5880 proves invaluable in applications craving increased capacitance. This feature plays a key role in achieving superior impedance matching and optimizing signal propagation in the intricate dance of high-frequency circuits.

Frequency-Range Stability: A hallmark of RT/duroid 5880 PCB is its ability to maintain stable electrical characteristics across a broad frequency range. This stability is a linchpin for consistent performance, adapting seamlessly to the demands of varying high-frequency environments.

Tailored Precision for High Frequencies: Offering customization to cater specifically to high-frequency circuits, RT/duroid 5880 PCBs stand as a bespoke solution. The material can be fine-tuned to overcome challenges that traditional PCBs might encounter in such demanding applications.

Impedance Mastery: RT/duroid 5880 enables controlled impedance design, a critical factor in high-frequency circuits. This capability ensures precise impedance matching, minimizing signal reflections and optimizing the seamless transfer of signals.

Dominance in RF and Microwave Realms: While traditional PCBs find their place in general electronic applications, RT/duroid 5880 takes center stage in RF and microwave systems. Its prowess in high-frequency precision makes it a preferred choice in communication systems, radar setups, and similar arenas where reliability at elevated frequencies is paramount.

Artistry in Design Flexibility: Beyond its material properties, RT/duroid 5880 PCBs offer a canvas of design flexibility. This agility in layout and routing is a valuable asset when navigating the complexities inherent in high-frequency circuitry.

In essence, RT/duroid 5880 PCB elevates itself above traditional counterparts by aligning its unique material characteristics with the intricate demands of high-frequency applications. Its low dielectric loss, high dielectric constant, stability across frequencies, and tailored precision position it as a distinctive choice for scenarios where the precision of high-frequency circuits takes precedence.

How is the Main Structure and Production Technology of RT/duroid 5880 PCB Defined?

Delving into the world of RT/duroid 5880 PCB unveils a meticulously defined main structure shaped by specialized production technology. Let’s unravel the intricacies:

Main Structure:

Substrate Symphony:

The heart of RT/duroid 5880 PCB lies in its substrate, a harmonious blend of woven glass fortified with polytetrafluoroethylene (PTFE). This composition sets the stage for unique electrical properties tailored for the demands of high-frequency applications.

Layered Tapestry:

The PCB unfolds as a layered tapestry, with substrate layers intricately stacked and interwoven with copper layers. The number of layers is a canvas, painted to accommodate the complexity dictated by the circuit’s design and application requirements.

Copper Ballet:

Copper layers perform a dance of conductivity, intimately bonded to the substrate through advanced techniques. These layers form the conductive pathways, shaping the circuitry with precision.

Dielectric Elegance:

The substrate material doubles as a dielectric layer, imparting low loss and a high dielectric constant. This dielectric elegance is key to the PCB’s performance in the realms of high frequencies.

Production Ballet:

Material Prelude:

The production overture begins with the meticulous preparation of the substrate material. The woven glass and PTFE undergo treatments to meet the exacting standards required for superior electrical performance.

Layered Choreography:

Layers, like skilled dancers, align themselves according to the choreography of the design. Precision is paramount in ensuring the accuracy and integrity of the final circuit.

Lamination Waltz:

Layers entwine in a lamination waltz, where heat and pressure fuse them into a cohesive entity. This dance results in a robust structure, ensuring a strong bond between substrate and copper layers.

Copper Etching Sonata:

The music of production continues with a copper etching sonata. Excess copper is delicately removed, revealing the defined conductive traces and circuit patterns dictated by the design.

Drilling Crescendo:

The production reaches a crescendo with precision drilling. Holes are orchestrated strategically for component placement and vias, aligning with the symphony of the circuit’s requirements.

Surface Finish Interlude:

An interlude ensues as the PCB’s surface is adorned with finishing touches. Solder mask and protective coatings create a polished surface, enhancing performance and safeguarding against environmental influences.

Quality Control Finale:

The grand finale incorporates rigorous quality control measures. Every note of the PCB’s performance is scrutinized through testing, ensuring it resonates perfectly with the specified electrical and structural requirements.

Customization Coda:

As a final note, RT/duroid 5880 PCB production may feature a customization coda. Adjustments to material properties or design optimization cater to the unique demands of specific high-frequency applications.

In essence, the production of RT/duroid 5880 PCB is a symphony of precision, with a carefully defined structure sculpted by specialized technology. The material’s properties and the artful dance of production techniques converge to create a PCB tailored for the intricate demands of high-frequency performance.

Frequently Asked Questions (FAQs)

What Defines RT/duroid 5880 PCB?

RT/duroid 5880 PCB stands as a specialized printed circuit board meticulously crafted for high-frequency realms. Its distinctive feature lies in a substrate woven from glass and fortified with polytetrafluoroethylene (PTFE), granting it unique electrical properties tailored for the intricacies of RF and microwave circuits.

What Sets RT/duroid 5880 PCB Apart?

Distinguishing itself from conventional PCBs, RT/duroid 5880 PCB boasts high-frequency prowess. With attributes like low dielectric loss, a high dielectric constant, and a focus on controlled impedance design, it becomes the preferred choice for applications where signal integrity in elevated frequencies is paramount.

Where Does RT/duroid 5880 PCB Find Application?

RT/duroid 5880 PCB finds its home in RF and microwave systems, communication devices, radar systems, and other domains where the demand for high-frequency precision is non-negotiable. Its specialized properties make it an ideal candidate in scenarios where traditional PCBs may face challenges in maintaining signal integrity.

How is RT/duroid 5880 PCB Crafted?

The production of RT/duroid 5880 PCB unfolds through a series of intricate steps. It commences with the meticulous preparation of substrate materials, progresses through layer alignment, lamination, copper etching, drilling, and culminates in surface finishing. Each stage is underpinned by stringent quality control measures to ensure the final PCB meets precise specifications.

Can RT/duroid 5880 PCB be Tailored for Specific Applications?

Absolutely. RT/duroid 5880 PCB stands as a canvas ready for customization to suit the unique demands of diverse high-frequency applications. This may involve tweaking material properties or optimizing the design to guarantee seamless compatibility and optimal performance.

What Advantages Does RT/duroid 5880 PCB Offer?

RT/duroid 5880 PCB presents a spectrum of advantages. Its excellence in high-frequency performance, coupled with low dielectric loss, high dielectric constant, and controlled impedance design, positions it as an ideal choice where traditional PCBs might falter in meeting the stringent demands of high-frequency circuits.

Conclusion

In the grand finale of the RT/duroid 5880 PCB narrative, we find a symphony of excellence harmonizing with the demands of high-frequency environments. From its woven substrate, delicately composed with glass and PTFE, to its intricate dance of features—low dielectric loss, high dielectric constant, and controlled impedance design—RT/duroid 5880 PCB emerges as a virtuoso, distinctly resonating in applications where conventional PCBs fall silent.

This bespoke creation finds its canvas in the expansive landscape of RF and microwave systems, communication devices, and radar setups. It steps onto the stage as a reliable performer, where the precision of high-frequency circuits takes center stage, conducting a melody of efficiency and reliability.

The production journey unfolds as a symphony, each note played with precision. From the careful preparation of substrate materials to the orchestrated dance of layer alignment, lamination, copper etching, and drilling, the process crescendos with surface finishing—a masterpiece underpinned by the vigilance of quality control.

Yet, RT/duroid 5880 PCB is not just a product; it is a canvas for customization. It invites the artist to tailor its material properties and design, crafting a unique melody that resonates with the specific demands of diverse high-frequency applications.

The advantages of RT/duroid 5880 PCB paint a vibrant portrait—high-frequency excellence, low dielectric loss, a commanding dielectric constant, and the precision of controlled impedance design. In a world where signal integrity is paramount, RT/duroid 5880 PCB stands tall as the virtuoso, orchestrating a symphony that minimizes losses and optimizes the dance of signals in RF and microwave applications.

In conclusion, RT/duroid 5880 PCB is not just a circuit board; it is a masterpiece, a symphony of design and material precision, tailored for the intricate demands of high-frequency circuits, where each performance is a testament to its excellence.

Flip-Chip Package Substrate manufacturer

Flip-Chip Package Substrate manufacturer